Unlocking Hidden Efficiency Gains in EV Auxiliary Systems

Electric vehicle (EV) engineers often invest millions to improve the main powertrain’s efficiency by fractions of a percent. Traction motors and inverters in modern EVs can already exceed 95% efficiency[1], so squeezing out an extra 0.1% is a costly challenge. Yet too often this hard-won gain is negated by overlooked auxiliary systems – the small motors and devices that support cooling, heating, steering, and other functions. It’s not uncommon for an EV maker to celebrate a 0.1% efficiency improvement in the propulsion system, only to lose that benefit by using a generic 12 V fan motor that might be only ~50% efficient[2]. In this article, we’ll explore how auxiliary systems efficiency affects overall EV efficiency and driving range. We’ll look at common auxiliary components, quantify their power draws and losses, and show with real-world values how improving their efficiency can meaningfully extend vehicle range. Finally, we’ll discuss strategies – including high-efficiency auxiliary motors – that can recapture wasted energy, with a spotlight on how iNetic’s UK-designed motors can help achieve these gains.

Diminishing Returns at 95%+

Electric drivetrains are remarkably efficient compared to internal combustion engines. The main traction motor in a typical EV operates somewhere between 80% and 95% efficiency[3][4], with many modern designs hitting the high end of that range. For example, iNetic’s own EV motors boast peak efficiencies above 96%. This means the vast majority of the battery’s electrical energy is converted into mechanical work to drive the wheels, with only a small fraction lost as heat.

Manufacturers continually refine motors, inverters, and gearboxes to approach theoretical efficiency limits. However, once you are at ~95% efficiency, gains become very incremental. Improving a 95% efficient traction system by even 0.1 percentage points (to 95.1%) yields a 0.1% increase in overall drive efficiency. In practical terms, if an EV consumes 20 kW while cruising at highway speed, a 0.1% efficiency boost saves only about 20 W of power – a nearly negligible difference in the context of a vehicle’s energy use.

Of course, every drop of improvement counts for extending range. But these last-mile optimizations often require expensive materials (e.g. better magnetic laminations, lower-loss semiconductors) or complex engineering. It’s a classic case of diminishing returns. As one EV expert quipped on an engineering forum, “a motor that’s 95% efficient isn’t much better in practice than one that’s 90%, especially if it costs ten times as much”[5]. In other words, beyond a certain point, chasing higher drivetrain efficiency may not be the most cost-effective way to improve an EV’s range.

Before pouring more resources solely into pushing the motor/inverter from 95% to 96%, it’s worth examining the rest of the vehicle. This is where auxiliary systems come in and where surprisingly large inefficiencies often hide.

The Hidden Energy Consumers in EVs

Every EV, like any modern car, has a host of auxiliary systems supporting the main driving function. Unlike the propulsion system, these auxiliaries don’t drive the wheels, but they consume energy from the battery to perform various necessary tasks. Common auxiliary components in a passenger EV include:

- Thermal Management Components: Electric coolant pumps circulate coolant to regulate battery and motor/inverter temperatures. Radiator fans (often 12 V electric fans) draw air through radiators or condenser coils for cooling the battery, power electronics, and sometimes the cabin. An air conditioning (A/C) compressor (electric motor-driven) cools and dehumidifies the cabin air in hot weather, and a PTC heater or heat pump provides cabin heating in cold weather. These thermal systems are among the largest auxiliary loads, often drawing several kilowatts under extreme conditions[6].

- Steering and Braking Assist: Nearly all modern EVs use electric power steering (EPS) instead of hydraulic assist. An electric motor (on the steering column or rack) provides steering boost on demand. Similarly, many vehicles have an electric vacuum pump or an electro-hydraulic booster to provide brake assist (since there’s no engine manifold vacuum as in an ICE vehicle). These motors run intermittently, but still add to the energy draw (power steering assist can add up to ~5% extra load under heavy use[7]).

- Cabin Accessories: The HVAC blower fan that circulates air inside the car, defrosters, heated seats, and other comfort features all consume power. The blower fan is essentially another electric motor (often a smaller 12 V DC motor) running whenever climate control is on. Window motors, seat adjusters, etc., are minor and used only briefly, but collectively the comfort and convenience features can account for a few percent of energy use[8].

- 12 V Electrical Loads: EVs still have a 12 V bus (and a small 12 V battery) to run traditional car electronics – lights, wipers, infotainment, sensors, and so on. Headlights (especially if LED) are fairly efficient, but when you add up all the exterior and interior lights, audio system amplifiers (which can be a few hundred watts[9]), and electronic control units, the total isn’t negligible. Fortunately, most of these are low-power or intermittent loads (on the order of tens or hundreds of watts each). In sum, “there are a number of traditional power consumption components like audio, lights, wipers, etc., but the amount of energy they consume is very small – regenerative braking energy gain is often enough to overcome that loss”[10]. The biggest continuous auxiliary draws remain climate control and thermal management systems.

- Auxiliary Power Consumption and Efficiency: Auxiliary systems in electric vehicles (EVs) can collectively draw a significant amount of power often several kilowatts. For an average EV, if 5 kW of power is used by auxiliaries from a 100 kW battery output, only 95 kW remains for propulsion. This directly reduces the driving range, since all energy whether for driving or auxiliaries comes from the same battery. Importantly, it’s not just the power draw that matters, but also how efficiently these auxiliary systems operate. Many EVs still have room for improvement in this area, as auxiliary systems are typically less efficient than the main powertrain.

Small Motors, Big Losses

Unlike the primary traction motor, which is optimized for high efficiency, auxiliary motors and devices often use simpler, cheaper designs with surprisingly low efficiency. A traditional brushed DC motor (the kind found in many 12 V fans, pumps, and older automotive accessories) might only achieve 50–80% efficiency in converting electrical power to mechanical power[2]. Many small motors operate closer to the lower end of that range. By contrast, the larger traction motors are typically brushless (BLDC or AC synchronous) and engineered for 90%+ efficiency under load.

To illustrate, consider a typical 12 V radiator cooling fan in a car. It might draw around 200 W when running at full speed. If the fan’s DC motor is, say, 50% efficient, that means only 100 W is actually being used to move air; the other 100 W is wasted as heat in the motor windings and brushes. In fact, data compiled by engineering researchers shows that small electric motors (~1 kW or less) can have efficiencies around 40–60%, whereas larger motors (>10 kW) easily reach 85–95%[12]. Small size and cost constraints make it challenging to design high-efficiency motors at low power – unless one specifically engineers a solution (which we’ll get to shortly).

Beyond the motor itself, there are other efficiency factors: the power conversion and the mechanical work output. Most auxiliaries in an EV run off the low-voltage system, meaning the high-voltage battery must step down to ~12 V (or 48 V in some newer designs) via a DC-DC converter. That converter isn’t perfect – it might be ~90–95% efficient. So if an auxiliary motor is drawing 200 W from the 12 V system, the high-voltage battery might supply ~220 W due to converter losses. And on the output side, the mechanical work (airflow, coolant flow, etc.) might itself not fully translate to useful effect – for instance, a pump’s hydraulic efficiency or a fan’s aerodynamic efficiency could be well below 100%. All told, the chain from battery to actual useful work done by an auxiliary can involve multiple loss points.

However, the motor efficiency is usually the biggest opportunity for improvement in that chain. Replacing a cheap brushed motor with a well-designed brushless motor can raise efficiency from ~50–60% to 85–90%[13], practically cutting losses by half or more. Likewise, using a higher voltage (48 V instead of 12 V) for auxiliaries can reduce current and resistive losses, improving the electrical efficiency. The key point is that unlike the main powertrain (already ~90+% efficient), auxiliaries often run at barely half efficiency, which means they draw double the electrical power for the same task, compared to an ideal case.

Let’s do a brief calculation to see how this inefficiency translates to range impact.

Side Calculation: Power Requirements with Different Efficiencies

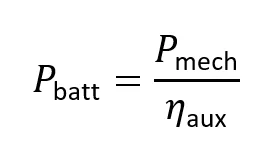

When a device (like a fan or pump) needs a certain mechanical power Pmech to do its job (e.g. move coolant), the electrical power it draws from the battery Pbatt depends on the efficiency of the whole chain:

Here θaux is the overall efficiency (motor × converter × etc.). If θaux is low, Pbatt is much larger than Pmech. For example, if a cooling pump needs to deliver 0.5 kW of mechanical power to circulate coolant at a required rate, and its motor is only 50% efficient, then Pbatt = 0.5 / 0.5 = 1.0 kW (plus a bit more to account for the DC-DC converter). A more efficient pump motor at 85% would only draw 0.5/0.85 approx. 0.59 kW for the same coolant flow – saving ~410 W. Over time, that difference is significant energy from the battery.

Now, let’s apply this kind of analysis to the whole vehicle in a driving scenario.

An Example Calculation

Consider a mid-size electric car with a 60 kWh battery pack. In steady cruising at 100 km/h on a mild day (no heavy A/C or heating needed), suppose the car’s main traction system consumes about 20 kW of power to overcome drag and rolling resistance. This is roughly in line with an energy use of 20 kWh per 100 km (200 Wh/km), giving an ideal range of 300 km from 60 kWh. Now we’ll see how auxiliary loads and their efficiencies can affect this range:

- Case 1: Low Auxiliary Load, Efficient Auxiliaries – First, assume auxiliaries are minimal or very efficient. Perhaps only 1 kW of auxiliary power is drawn (things like EPS, fans at low speed, electronics). If that 1 kW is delivered with high efficiency (say 90%), the battery might supply ~1.1 kW to cover it. Total power draw becomes 21.1 kW. The energy consumption rises slightly to ~21.1 kWh per 100 km, and the range would drop from 300 km to about 284 km. That’s a ~5% range reduction due to auxiliaries, which is modest.

- Case 2: High Auxiliary Load, Inefficient Auxiliaries – Now imagine a more demanding scenario: a very hot day where A/C is on max, drawing a significant 5 kW of cooling power (for cabin and battery cooling). If the A/C compressor and fans are inefficient, they might pull double that from the battery – say 10 kW – to produce 5 kW of cooling (this could happen if the system efficiency is ~50%). Add other loads averaging another 1 kW, and we have ~6 kW needed for aux, potentially costing ~12 kW from the battery in total. Now the car’s total power draw is 20 kW (traction) + 12 kW (aux) = 32 kW. Energy consumption soars to 32 kWh/100 km, and the range plummets to only ~188 km on a full 60 kWh charge! In percentage terms, the range loss is on the order of 35–40%. Indeed, studies and real-world fleet data confirm that running A/C or heat at full blast can slash an EV’s range by 30% or more[7][14].

- Case 3: High Aux Load, Efficient Auxiliaries – What if we improve the auxiliaries? Suppose the same 5 kW of cooling is delivered by advanced AC motors and a heat pump system that together achieve, say, 80% overall efficiency. The battery would then supply about 6.25 kW (5/0.8) for A/C instead of 10 kW. Including other loads, maybe 7.25 kW total for auxiliaries. Now total draw is 27.3 kW (20 + 7.3). Consumption ~27.3 kWh/100 km, range ~220 km. Compared to the inefficient case, that’s a recovery of ~32 km of range (220 km vs 188 km) just by using better auxiliary system design. The range hit is ~27% instead of ~37% – still significant, but notably less harmful.

These simplified cases show that auxiliary systems can make or break the real-world range of an EV. In moderate conditions, auxiliary loads can trim a few percent off the range (which is why you often see slightly lower range in city driving with accessories on). In extreme conditions, inefficient auxiliaries are essentially siphoning away a chunk of the battery’s energy. It’s little wonder that cold winters (needing resistive heating) or heat waves (A/C at full blast) are notorious for causing EV drivers to see much lower range than advertised[15].

To further underscore this: if an automaker spent a fortune improving the drivetrain efficiency from 90% to 95% (which might save maybe 5–10% energy in the powertrain), but ignored an auxiliary system that wastes 2 kW continuously, the benefit of the powertrain gains could be completely erased by that single auxiliary loss. A holistic approach is clearly needed, looking at the car as an entire system.

Big Gains from Small Motors

Use High-Efficiency Electric Motors for Auxiliaries

Replacing brushed 12 V motors with high-efficiency permanent magnet motors can drastically cut losses. Brushless motors have no brush friction and can be optimized with electronic control for peak efficiency at the typical operating point. They routinely achieve 80–95% efficiency[13], versus ~50% for a cheap brushed unit[2]. For example, brushless radiator fans and coolant pumps are now offered in the aftermarket and by OEMs; they not only consume less power for the same airflow/flow rate but also run quieter and more reliably (no brushes to wear out)[16][17]. Similarly, modern EVs often use an electric A/C compressor with an internal high-voltage BLDC motor. Ensuring that compressor motors are high-quality can save a lot of energy during climate control use. In short, upgrading the auxiliary motors can yield efficiency gains far larger than a 0.1% overall improvement – we are talking gains of several tens of percent in the aux subsystem, which translates to tangible range increase.

Optimize Thermal Management System Design

The thermal system (battery and cabin conditioning) is usually the number-one auxiliary energy hog. Using a heat pump for cabin conditioning (as opposed to simple resistive heaters) can dramatically improve cold-weather efficiency, essentially multiplying the heat output per watt of input by 2x or 3x via refrigeration cycle. Many new EVs now come with heat pumps and see far smaller winter range drops. On the cooling side, a well-designed coolant loop that uses variable-speed pumps and fans (only as much as needed) and isolates sections when not needed can reduce waste. Instead of one big pump pushing coolant everywhere (some of which may not need cooling at the moment), intelligent cooling control can target the cooling to where it’s needed and run pumps at lower speeds when possible, saving energy. This also ties back to motor selection – variable-speed capability in auxiliaries (enabled by brushless motors and electronic control) is crucial. It allows, for example, a fan to run at half speed (with far lower power draw) if full cooling isn’t required, rather than an inefficient on/off full-blast operation.

Higher System Voltage or Direct HV Auxiliaries

A trend in the industry is moving some auxiliaries to 48 V systems (for mild hybrids) or even running certain large auxiliaries (like A/C compressors) directly off the high-voltage pack via dedicated inverters. The rationale is to avoid the bottleneck of 12 V conversion and high currents. A higher voltage means lower current for the same power, which reduces resistive (I²R) losses in wires and allows smaller, more efficient motors (since they can be designed for higher voltage, lower current). While a full 48 V architecture in EVs is not universal, certain components like electric power steering or electric turbo compressors in performance EVs use higher than 12 V. Optimizing the DC-DC converter efficiency (e.g. using synchronous rectification, soft-switching) also ensures minimal loss in feeding the auxiliaries.

Smart Energy Management

Software can play a role too. For instance, if an EV knows it is low on charge, it could proactively scale back auxiliary usage – dimming climate settings, slowing down HVAC fan speeds, etc., or opportunistically cycling pumps only as needed. Some EVs already have “Eco Mode” settings that do part of this, trading a bit of comfort for extra range. The smarter the energy management, the less waste.

Investing in Efficient Auxiliary Solutions

Improving auxiliary systems does require upfront effort and sometimes cost. High-efficiency motors and advanced control electronics can be more expensive than off-the-shelf 12 V brushed motors and relays. However, the payoff is a more efficient vehicle with better range and potentially longer component life. This is where companies like iNetic come into play, providing the engineering know-how and manufacturing capability to supply custom high-efficiency motors for these exact needs.

iNetic’s Role in High-Efficiency Auxiliary Motors

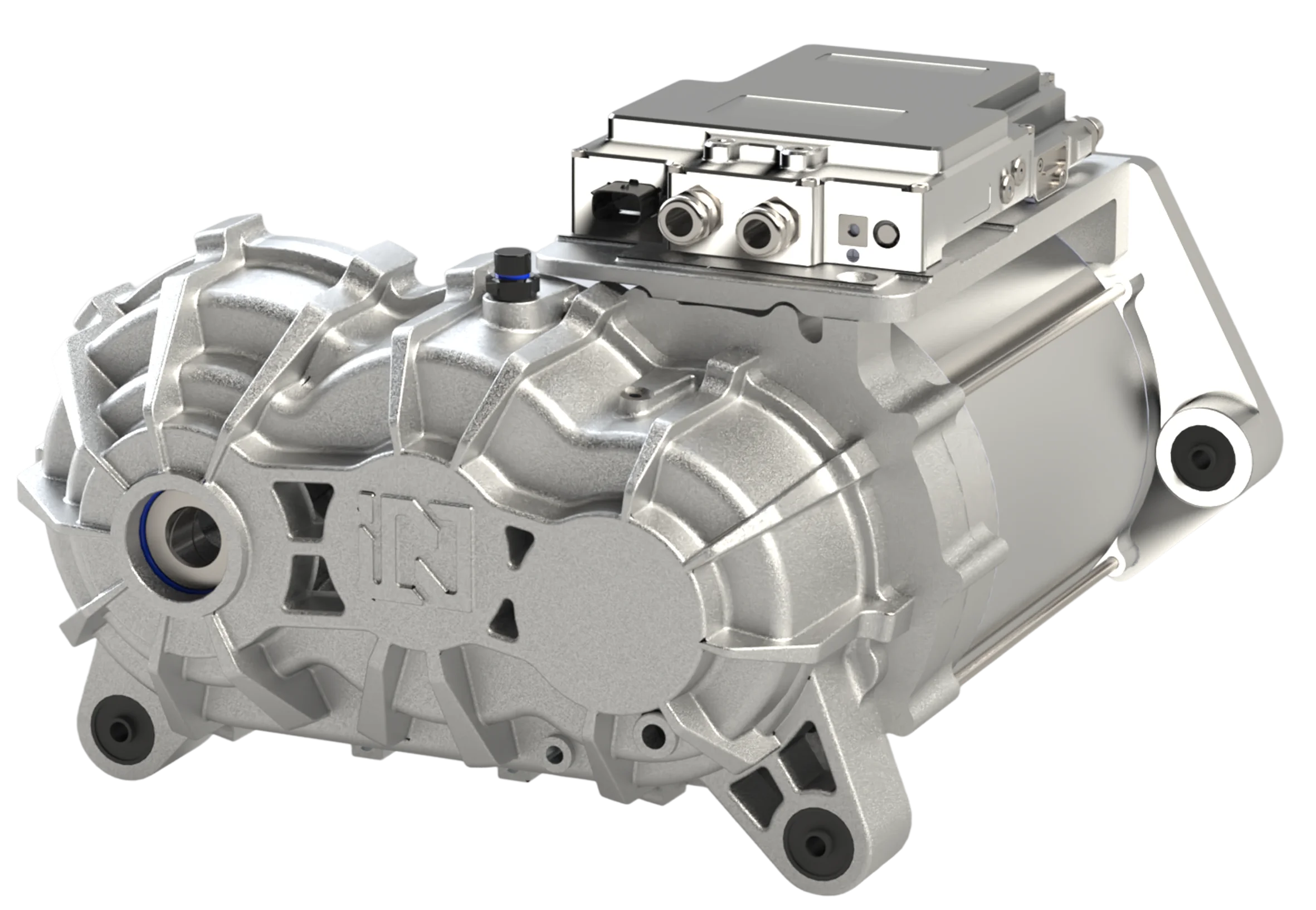

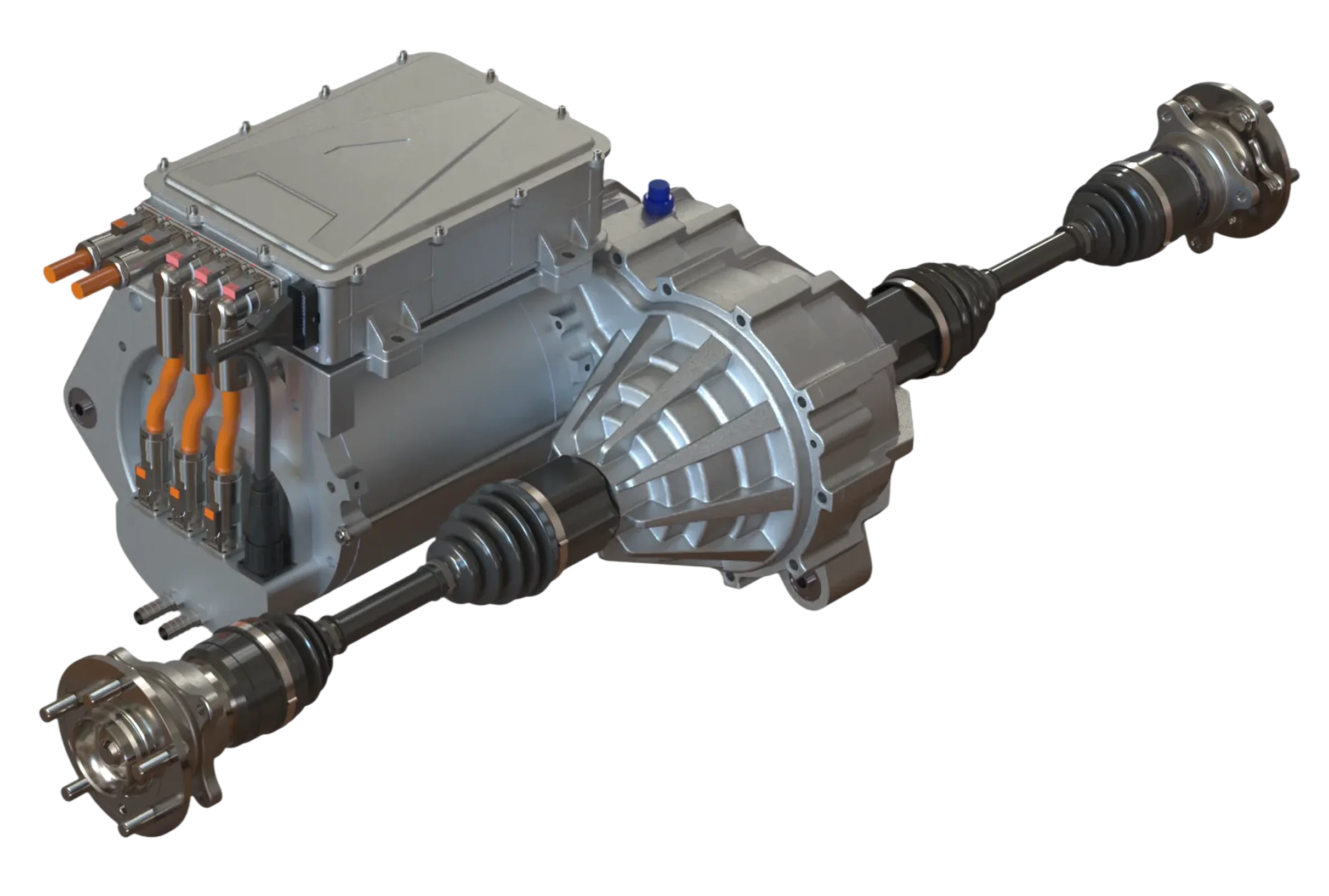

iNetic is a trusted electric motor manufacturer based in the UK[18], known for designing and producing motors that “combine performance, efficiency, and durability”[19]. While a lot of attention goes to our traction motors (for example, the iNetic Traction line for 400–800 V drivetrains), the same expertise can be applied to smaller motors for auxiliary applications. In fact, iNetic’s design philosophy emphasizes high efficiency at all scales and we are committed to developing energy-efficient motor solutions that reduce energy waste and carbon footprint[20]. This approach aligns perfectly with optimizing auxiliary systems in EVs.

For instance, iNetic can develop a compact motor for a coolant pump or radiator fan, tailored to the voltage and performance requirements of the EV’s architecture. By using advanced electromagnetic design, low-loss materials, and precision manufacturing, such a motor can significantly outperform the typical commodity motor in both efficiency and power density. The result is an auxiliary unit that delivers the required cooling with minimal draw on the battery. Likewise, for applications like electric oil pumps, fuel-cell air compressors, or HVAC blowers, iNetic’s engineering team can offer a range of low power high-efficiency motors or even bespoke motor solutions that meet high performance specs while operating at efficiencies close to those of much larger drive motors. These improvements directly translate to more miles per charge for the end user.

Moreover, because iNetic is based in the UK with local manufacturing, EV companies can benefit from a shorter supply chain and collaborative development. Instead of ordering a generic part from overseas and hoping it fits the bill, an automaker or EV startup can work with iNetic to co-design auxiliary motors optimized for their system, ensuring both peak efficiency and seamless integration. This not only boosts the vehicle’s efficiency but also supports UK innovation and manufacturing, a win-win scenario for technology and the economy.

Conclusion

Efficiency in an electric vehicle is a game of managing every watt. While the spotlight often shines on the big-ticket items like the battery and drive motor, the auxiliary systems collectively can make a decisive difference in how far an EV goes on a charge. It’s a bit ironic: after achieving ~90–95% efficiency in the main powertrain, overlooking an auxiliary motor that’s only ~50% efficient is like letting the proverbial “efficiency leak” undermine the whole system. As we highlighted, running multiple small motors and devices at suboptimal efficiency adds up, it can chop 5%, 10%, or even 30% off the driving range depending on conditions[7].

The encouraging takeaway is that these losses are not inherent to EVs; they can be addressed with smart engineering. By upgrading auxiliary components; high-efficiency motors, better thermal systems, intelligent controls, automakers and suppliers can recapture energy that would otherwise be wasted. This yields a double benefit: drivers get more range (or need less battery capacity for the same range), and the vehicle’s overall energy usage (hence emissions, if grid electricity is considered) is reduced. It’s a sustainability win in line with the EV mission.

At iNetic, our mission is exactly aligned with this: delivering innovative electric motor solutions that maximize performance and efficiency, for applications large and small. We pride ourselves on a UK-based design and manufacturing capability that can rise to these challenges; whether it’s a 200 kW traction motor or a 2 kW auxiliary pump motor. By focusing on every detail of the electric drive system, including the “auxiliaries,” we help our partners build EVs that go further, last longer, and use energy more wisely. In the drive towards better electric vehicles, remember that efficiency isn’t just about the big motor – sometimes, it’s the little motors behind the scenes that make all the difference.

Sources:

- BatteryDesign.net – Auxiliary systems power consumption in electric vehicles[11][6]

- INL/avt – EV Auxiliary Systems Impacts (impact of A/C, heating on range)[7][14]

- Engineering Toolbox – Fans: Efficiency and Power Consumption (motor efficiency vs size)[12]

- Tyto Robotics – DC vs AC vs BLDC Motor Efficiency (DC motor 50–80% efficient)[2]; (BLDC 80–95% efficient)[13]

- BorgWarner Inc. – Electric Drive Motors (EV traction motor peak >95% efficient)[1]

- DeWitts Radiators – The Power of Brushless (benefits of brushless fans)[16]

- iNetic (UK) – Company Info and Vision (focus on high-efficiency motor design and UK manufacturing)[19][20]

[1] Electric Drive Motors

https://www.borgwarner.com/technologies/electric-drive-motors

[2] [13] AC vs DC vs BLDC Motor Efficiency Comparison – Tyto Robotics

[3] [4] Status of Pure Electric Vehicle Power Train Technology and Future Prospects

https://www.mdpi.com/2571-5577/3/3/35

[5] New GE advanced traction motor | Endless Sphere DIY EV Forum

https://endless-sphere.com/sphere/threads/new-ge-advanced-traction-motor.44036/

[6] [9] [10] [11] Auxiliary systems power consumption in electric vehicles – Battery Design

https://www.batterydesign.net/auxiliary-systems-power-consumption-in-electric-vehicles/

https://avt.inl.gov/sites/default/files/pdf/fsev/auxiliary.pdf

[12] Fans – Efficiency and Power Consumption

https://www.engineeringtoolbox.com/fans-efficiency-power-consumption-d_197.html

[16] [17] The Power of Brushless – DeWitts™ Direct Fit® Aluminum Radiators

[18] [19] [20] iNetic – Leading Electric Motor Manufacturer in the UK