iNetic's iPA System Powers the Next Generation of MEWPs

At iNetic, we believe that electrification isn’t just about replacing diesel engines — it’s about rethinking how machines deliver power, control, and efficiency. That philosophy is at the heart of our latest project: integrating our fully integrated electro-hydraulic drive system — the iPA — into a Mobile Elevated Work Platform (MEWP). This initiative is part of a collaborative effort alongside our partners EV Parts and Quattro Group, bringing together advanced engineering, deep system knowledge, and real-world fleet expertise.

This transformation demonstrates how electric powertrains can meet the complex demands of off-highway machinery while delivering significant performance and environmental benefits.

A Collaborative Mission to Decarbonise Off-Highway Machinery

The project began with a clear objective: to retrofit an existing MEWP (Mobile Elevated work platform) with a fully electric drive system that meets or exceeds the original diesel performance, but with zero tailpipe emissions and dramatically reduced noise levels.

The challenge was both technical and practical. The machine needed to retain full lifting and travel capability, while ensuring safety, reliability, and operator familiarity. The result would not only serve as a proof-of-concept but form the basis of a scalable retrofit kit that could be applied to similar platforms across the Quattro fleet and beyond.

Designing the Retrofit Kit: Engineering in the Real World

Developing the retrofit kit was a multi-phase process:

1. System Baseline & Teardown

Our engineering team conducted a detailed analysis of the MEWP’s existing hydraulic, electrical, and thermal systems, mapping out every connection, load profile, and control logic. This included CAN bus mapping, lifting cycle profiling, and space claim analysis in the engine bay.

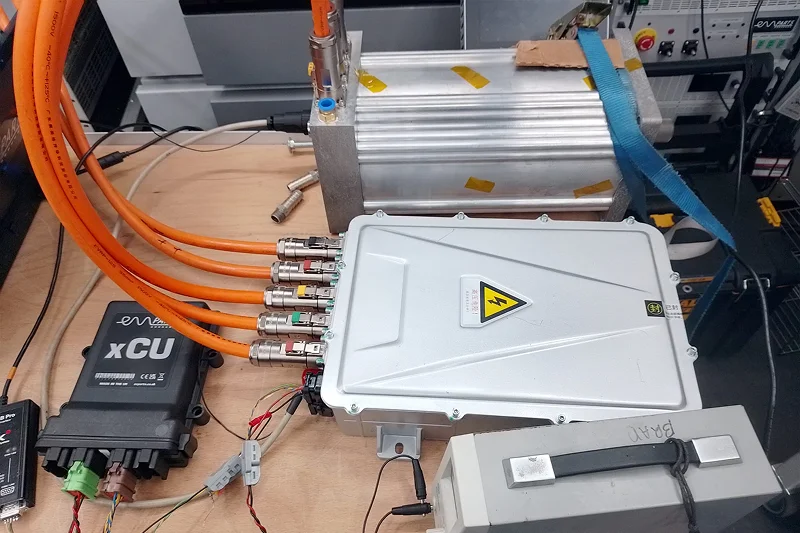

2. Selecting the Right Drive System

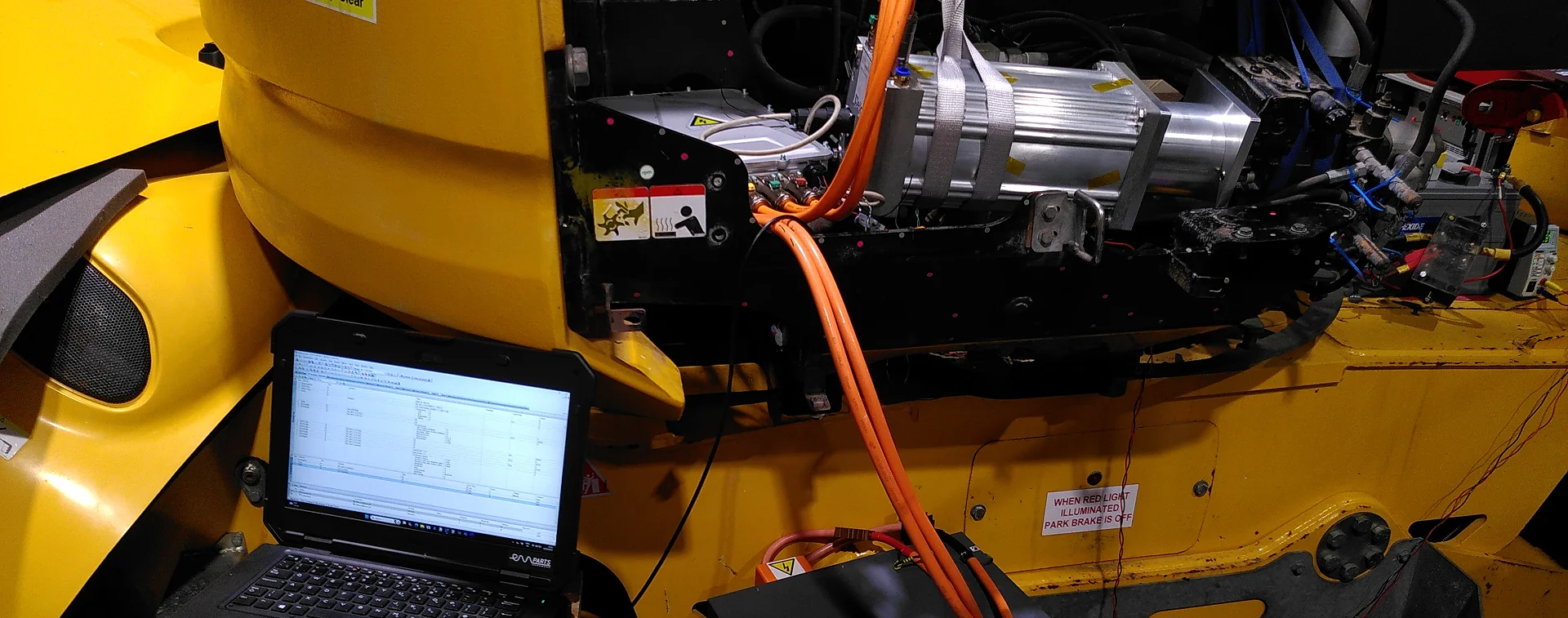

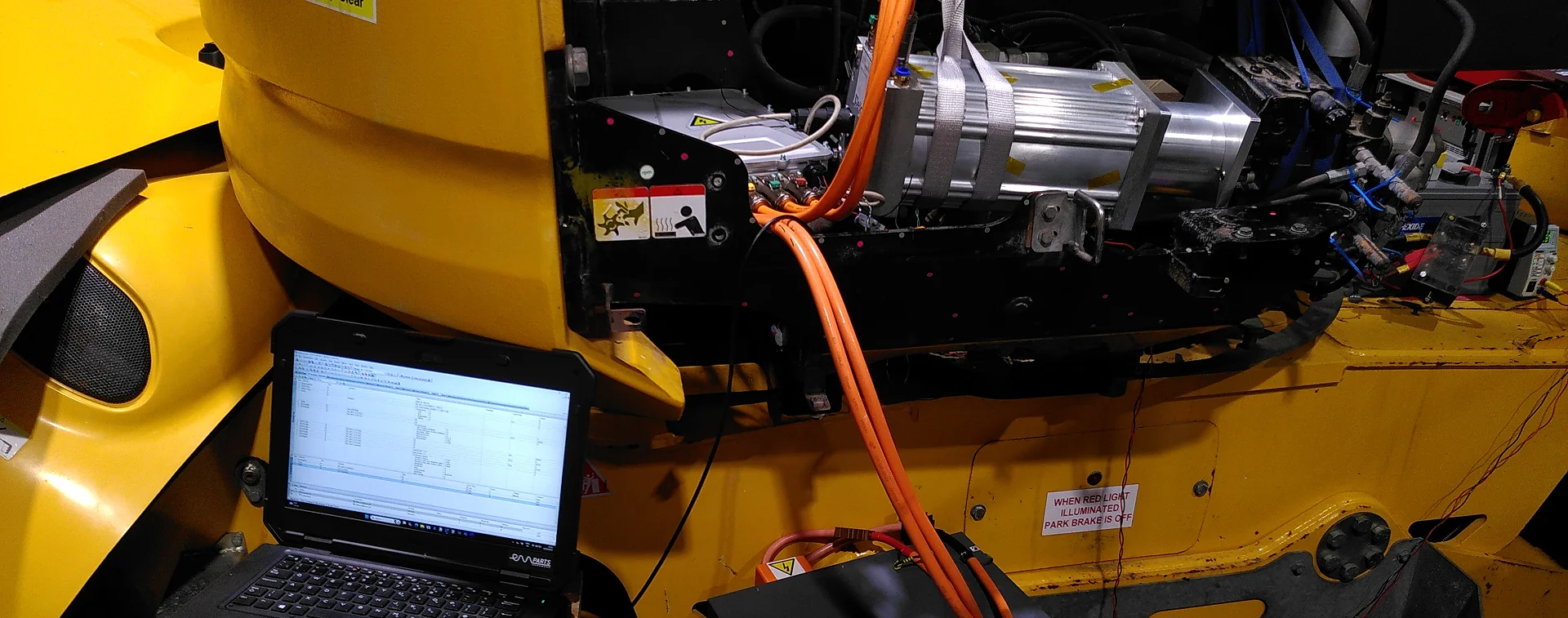

We used this data to specify and size the iPA unit, a fully integrated electric motor, inverter, and hydraulic pump system, capable of delivering over 31kW peak power at 2500rpm, matching the diesel engine’s continuous performance.

3. Thermal & Power System Design

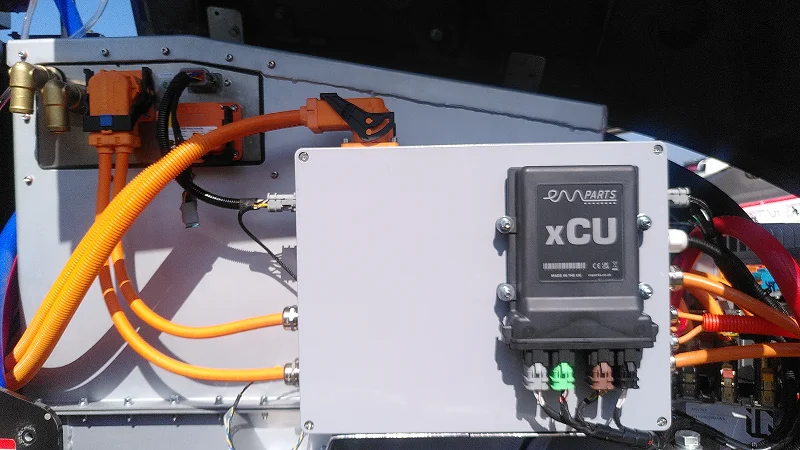

EV Parts led the design of a highly efficient battery and controls system, while the Quattro team developed a robust thermal management system. This includes a 60kWh lithium-ion pack with active heating and cooling, enabling full-shift performance under the most demanding conditions (a simulated 12-hour extreme usage shift).

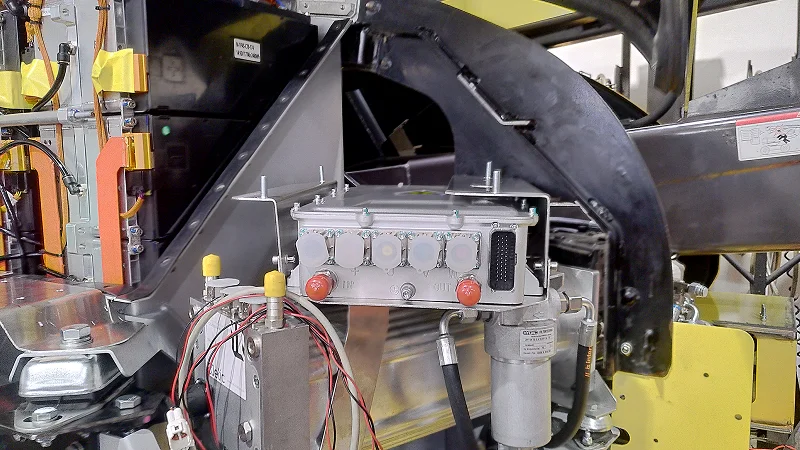

4. Mounting and Integration

A new modular frame was designed to install the electric motor and battery into the existing engine bay, maintaining structural balance and weight distribution. All electrical and hydraulic connections were adapted to retain compatibility with the MEWP’s original control systems.

5. Safety and Control

Redundant safety systems were engineered, including emergency descent powered by an AGM backup battery, and a control interface was developed that mimics the original diesel experience. This reduced operator training time and ensured continuity with existing operational protocols.

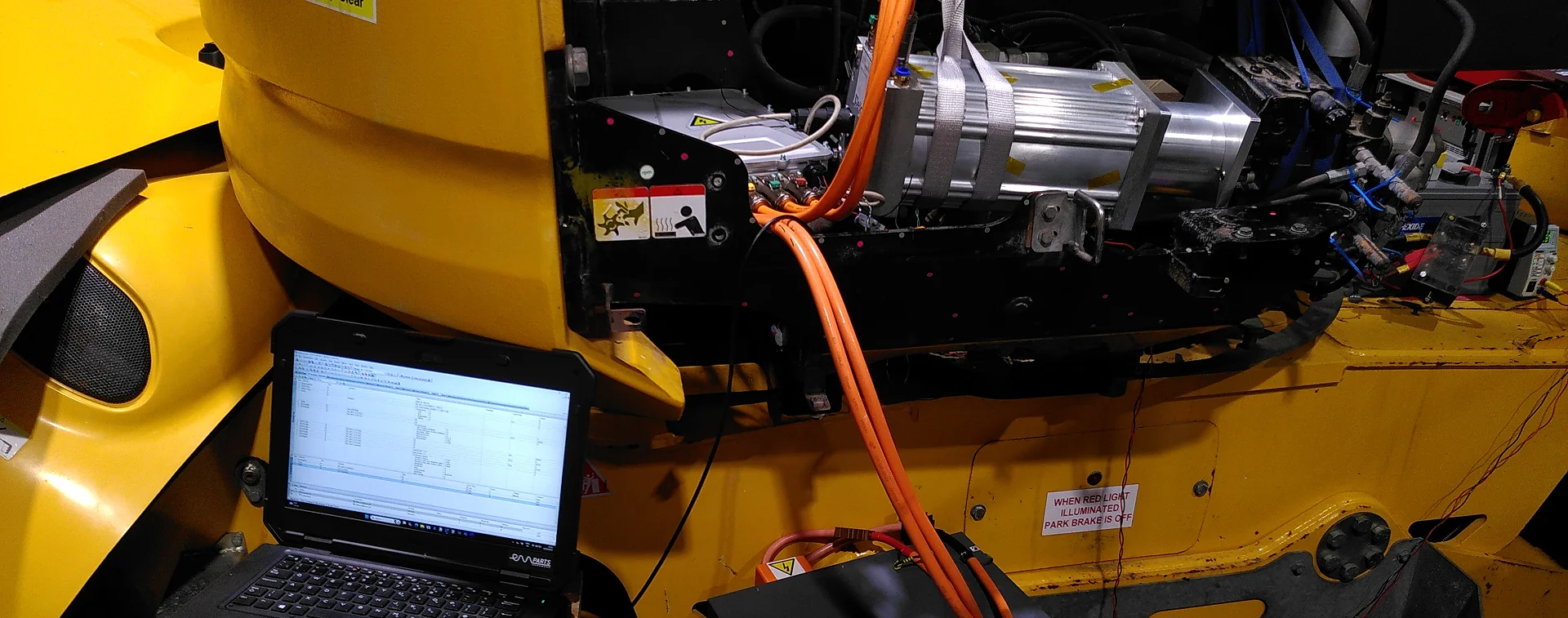

6. Testing and Validation

The complete system underwent rigorous bench testing and field trials, validating lift performance, travel capabilities, gradient climbing, noise levels, and battery endurance.

A Platform for the Future

A Platform for the Future

The iPA Advantage in Action

The iPA system brings several advantages to the converted MEWP:

Energy Efficiency: The system only draws power when required, eliminating idling losses common in diesel engines and extending effective runtime.

Quieter Operation: Acoustic emissions dropped from over 100 dB(A) to below 83 dB(A), a dramatic reduction that improves worksite safety and community impact.

Modular Retrofit: The design can be scaled and repeated across similar machines, offering a path to low-cost, high-impact fleet decarbonisation.

Battery Optimisation: Intelligent control strategies adapt voltage range usage across the battery’s lifespan to maximise useful energy while extending service life.

Enhanced Cooling: A combined cooling loop utilises heat exchange between hydraulic, motor, and battery systems, optimising performance in cold and hot conditions.