Introduction

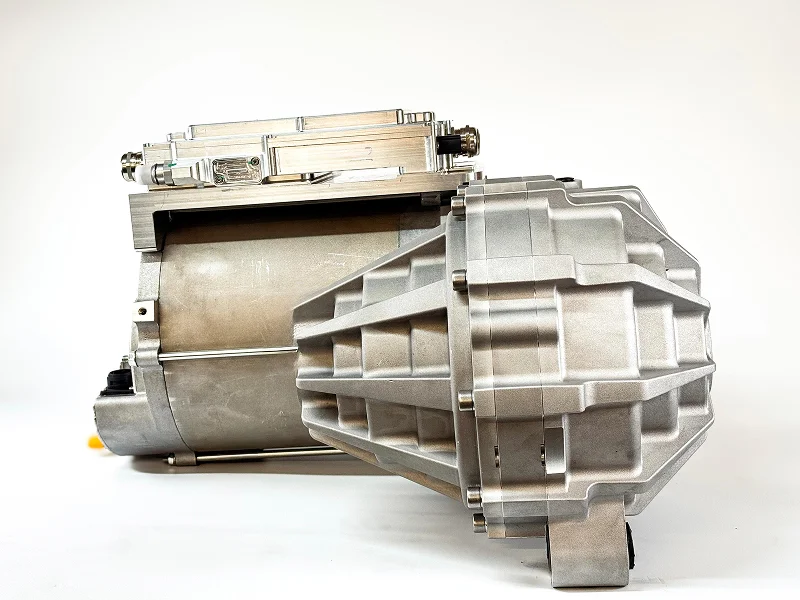

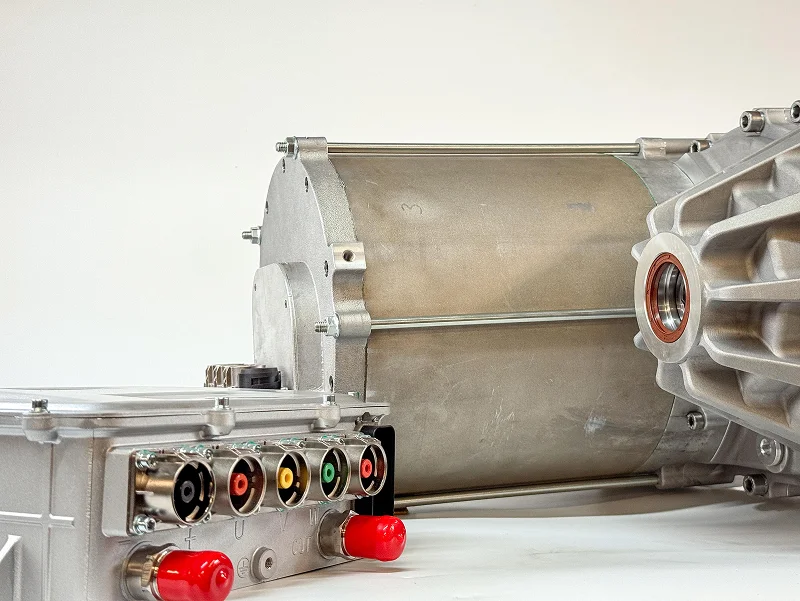

Electric drive units (EDUs) must operate reliably across a wide range of road grades and duty cycles, especially in commercial and off-road applications. For the iNetic rDA gearbox, a critical factor in maintaining consistent performance across inclines and declines is gearbox oil gradability, the ability of the gearbox to maintain optimal lubrication regardless of vehicle pitch.

This article unpacks the findings from a comprehensive oil level study carried out on the gearbox used in the iNetic rDA EDU. The analysis ensures reliable gear lubrication across multiple gradient scenarios.

What Is Gearbox Gradability?

Gearbox gradability refers to the gearbox’s ability to remain adequately lubricated under varying incline and decline angles. This is particularly vital in applications such as electric vans, trucks, or off-road vehicles, where steep slopes are common.

Poor gradability can lead to:

- Inadequate lubrication of critical gears and bearings

- Increased wear and heat

- Potential gearbox failure

The goal is to optimise the oil level and fill volume to ensure that even at extreme angles, oil remains in contact with moving components.

Gearbox gradability refers to the gearbox’s ability to remain adequately lubricated under varying incline and decline angles. This is particularly vital in applications such as electric vans, trucks, or off-road vehicles, where steep slopes are common.

Poor gradability can lead to:

- Inadequate lubrication of critical gears and bearings

- Increased wear and heat

- Potential gearbox failure

The goal is to optimise the oil level and fill volume to ensure that even at extreme angles, oil remains in contact with moving components.

The Study: Gearbox Oil Filling & Angles

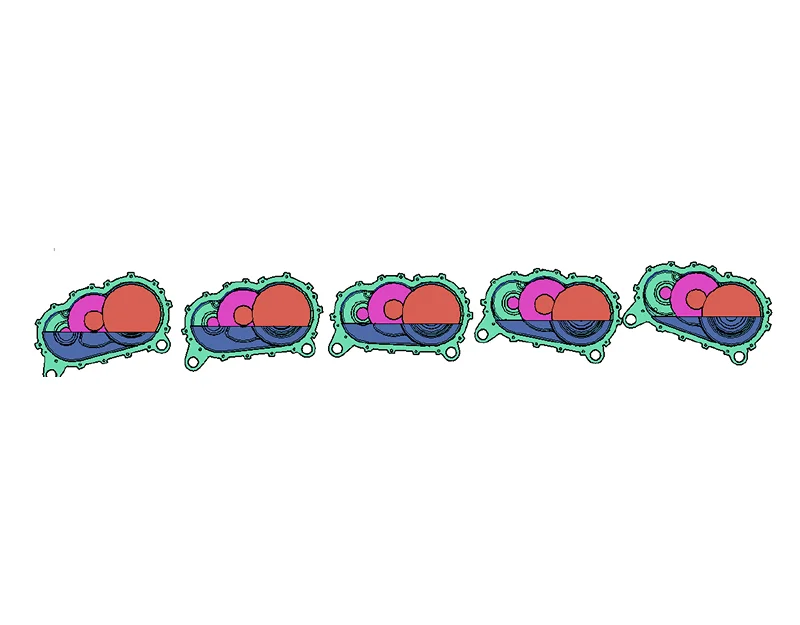

To assess the oil gradability of the iNetic rDA gearbox, eight different oil level cases were simulated and tested. These cases varied the oil volume and evaluated the oil’s free surface under different pitch angles.

Each scenario measured how well the internal gears remained submerged in oil under extreme frontward or rearward vehicle inclinations.

To assess the oil gradability of the iNetic rDA gearbox, eight different oil level cases were simulated and tested. These cases varied the oil volume and evaluated the oil’s free surface under different pitch angles.

Each scenario measured how well the internal gears remained submerged in oil under extreme frontward or rearward vehicle inclinations.

The Study: Gearbox Oil Filling & Angles

The Study: Gearbox Oil Filling & Angles

To assess the oil gradability of the iNetic rDA gearbox, eight different oil level cases were simulated and tested. These cases varied the oil volume and evaluated the oil’s free surface under different pitch angles.

Each scenario measured how well the internal gears remained submerged in oil under extreme frontward or rearward vehicle inclinations.

Case Studies and Results

The gearbox was tested across eight oil fill levels, gradually increasing the oil quantity. Each case simulated real-world pitch angles to identify when gear exposure occurred.

Case Highlights:

Case 1–3: Lower oil fill volumes. Resulted in insufficient lubrication at inclines greater than ±10°.

Case 4–6: Intermediate fill levels. Improved coverage but still risked exposure during steep pitch scenarios.

Case 7–8: Higher oil fill levels. Provided consistent coverage across all pitch angles up to ±20°, demonstrating the best gradability.

Key finding: A minimum fill level of Case 7 or higher is recommended to ensure safe operation up to ±20° pitch.

The gearbox was tested across eight oil fill levels, gradually increasing the oil quantity. Each case simulated real-world pitch angles to identify when gear exposure occurred.

Case Highlights:

Case 1–3: Lower oil fill volumes. Resulted in insufficient lubrication at inclines greater than ±10°.

Case 4–6: Intermediate fill levels. Improved coverage but still risked exposure during steep pitch scenarios.

Case 7–8: Higher oil fill levels. Provided consistent coverage across all pitch angles up to ±20°, demonstrating the best gradability.

Key finding: A minimum fill level of Case 7 or higher is recommended to ensure safe operation up to ±20° pitch.

Free Surface Angle Analysis

An essential part of the study was understanding how oil sloshes and redistributes during pitch changes. The oil free surface angle shifts significantly at steep gradients, potentially uncovering gear teeth.

Through computational analysis, the team was able to map the oil’s free surface at multiple angles and match this against gear positions, ensuring full submersion in high-load areas.

An essential part of the study was understanding how oil sloshes and redistributes during pitch changes. The oil free surface angle shifts significantly at steep gradients, potentially uncovering gear teeth.

Through computational analysis, the team was able to map the oil’s free surface at multiple angles and match this against gear positions, ensuring full submersion in high-load areas.

Design Implications for iNetic rDA EDU

From this study, several key recommendations were implemented into the rDA EDU design:

- Optimized oil fill to ensure gear coverage across full operating range

- Venting and breather strategies to handle oil slosh without leakage

- Tilt-tolerant casing geometry that channels oil back to high-stress areas

These adjustments make the iNetic rDA gearbox suitable for urban delivery vehicles, off-highway machinery, and other slope-intensive operations.

From this study, several key recommendations were implemented into the rDA EDU design:

- Optimized oil fill to ensure gear coverage across full operating range

- Venting and breather strategies to handle oil slosh without leakage

- Tilt-tolerant casing geometry that channels oil back to high-stress areas

These adjustments make the iNetic rDA gearbox suitable for urban delivery vehicles, off-highway machinery, and other slope-intensive operations.

Summary

Gearbox gradability is not just a theoretical design factor—it directly impacts real-world reliability. The OX gearbox study proves that with careful oil volume management and design considerations, electric drive units like the iNetic rDA can achieve robust, pitch-independent performance.

Recommended Oil Fill: Level 7 or higher

Max Pitch Tolerance: ±20° with consistent lubrication

Application Ready: For harsh gradients and heavy-duty cycles

Further Reading & Contact

For more information on the iNetic rDA EDU or to request the full oil level study, get in touch with the iNetic Traction team at www.inetictraction.com