The Electrification Boom and the Automotive Mirage

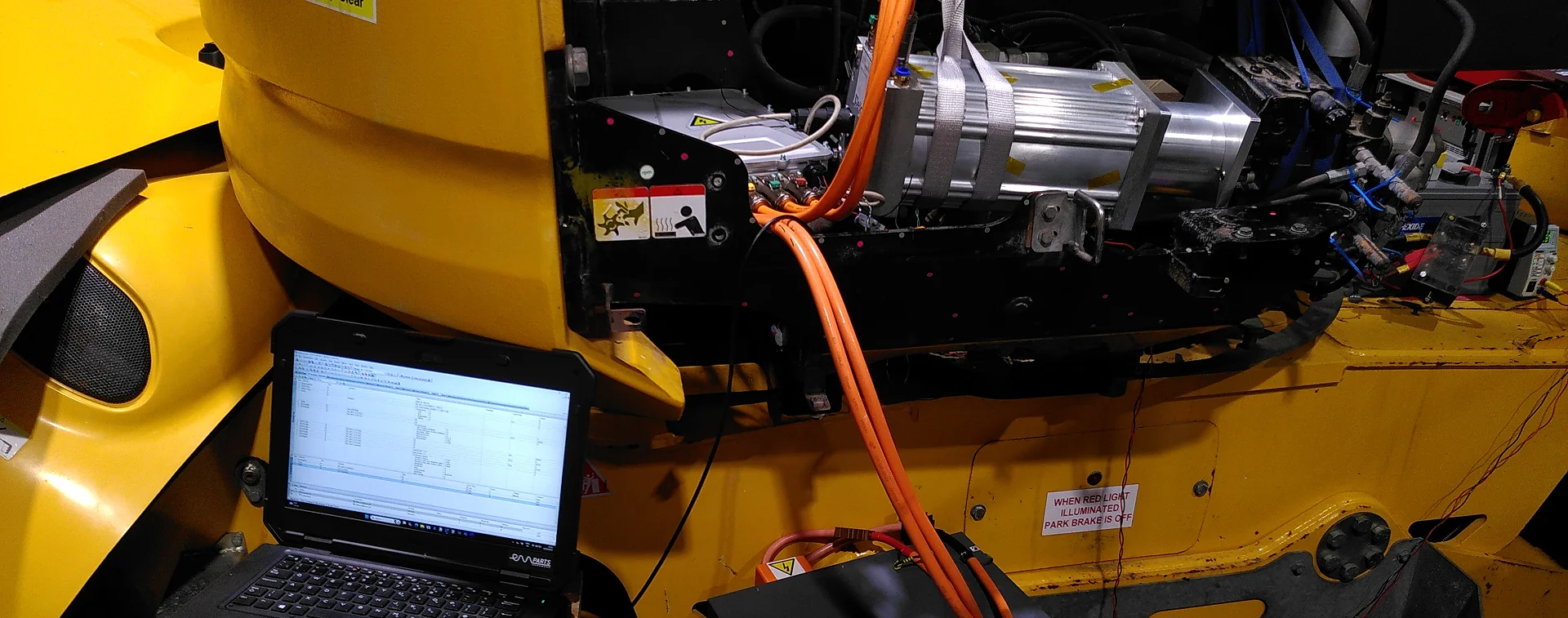

Off-highway electrification has moved from possibility to inevitability. Across construction, agriculture, and mining, OEMs are under pressure to deliver cleaner, quieter, and lower-cost machines. With the off-highway electric vehicle (OHEV) market expected to grow from around $8 billion in 2024 to over $80 billion by 2033, this is no longer an early-adopter phase – it’s an industrial revolution.

Compact machinery (30–150 HP) is electrifying first, with heavy-duty (>200 HP) platforms following by the end of the decade. The drivers are clear:

- Regulation & Zero-Emission Zones: Urban projects increasingly mandate low-noise, zero-emission operation.

- Operating Efficiency: Electric drivetrains cut energy and maintenance costs dramatically.

- Performance & Productivity: Instant torque and precise control improve digging, lifting, and towing performance.

For OEMs, the challenge is no longer whether to electrify – but how. And here lies the most dangerous shortcut: repurposing an automotive motor.

Why It Fails Off-Highway

Passenger EV components are seductive. They promise high efficiency, lightweight packaging, and low cost. But automotive drivetrains are optimised for smooth tarmac and predictable duty cycles – not for the relentless punishment of an excavator, tractor, or haul truck.

Automotive motors are designed to:

- Operate at high speed (10,000 – 18,000 RPM) for long highway drives.

- Deliver brief bursts of peak torque for acceleration, not continuous heavy loading.

- Depend on airflow-based cooling, effective only when the vehicle is moving quickly.

In contrast, off-highway machines:

- Demand continuous torque at low or zero speed.

- Endure severe vibration and shock loads.

- Operate in dust, mud, and high-pressure washdown environments.

This mismatch is catastrophic. Forcing a road-car motor into a digger or loader means asking it to live permanently in its least efficient, most thermally stressed operating zone. It overheats, demagnetises, and mechanically fails – not hypothetically, but predictably.

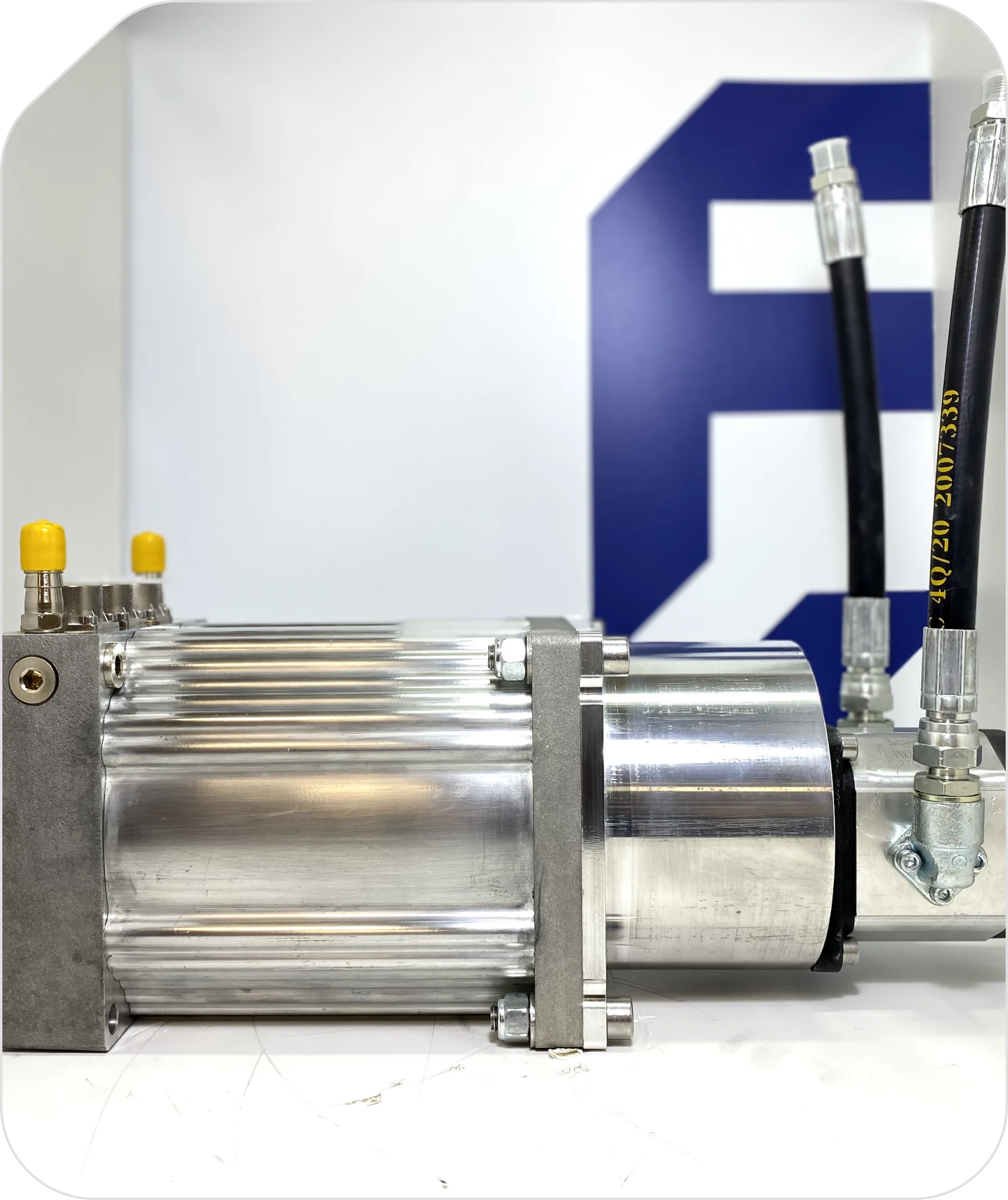

iNetic’s iPA PMSM for Off-Highway Applications

The answer is not to “adapt” an automotive design but to select a motor engineered from the outset for the off-highway duty cycle. That’s the philosophy behind the iPA series from iNetic – a family of Permanent Magnet Synchronous Motors (PMSMs) optimised for rugged, industrial environments.

1. Optimised Winding for Continuous Torque

Unlike automotive PMSMs that target high-speed efficiency, the iPA’s electromagnetic design is tuned for sustained high torque at low speed. The winding design, slot geometry, and cooling paths are optimised for continuous current capability rather than short-term bursts. This ensures the motor can hold load, push hydraulic systems, or drive traction directly without overheating—ideal for excavators, telehandlers, and agricultural implements.

2. Mechanical Robustness for Shock and Vibration

Off-highway duty cycles impose brutal mechanical demands. The iPA platform is structurally engineered to absorb high-g shocks and continuous vibration:

– High-grade bearings, reinforced shaft design, and a rigid rotor-stator interface ensure mechanical integrity under percussive loads.

– Windings are fully impregnated or potted, eliminating micro-movement and preventing insulation wear under vibration.

– The result: exceptional longevity even under SAE J1455 / ISO 15003 mechanical standards.

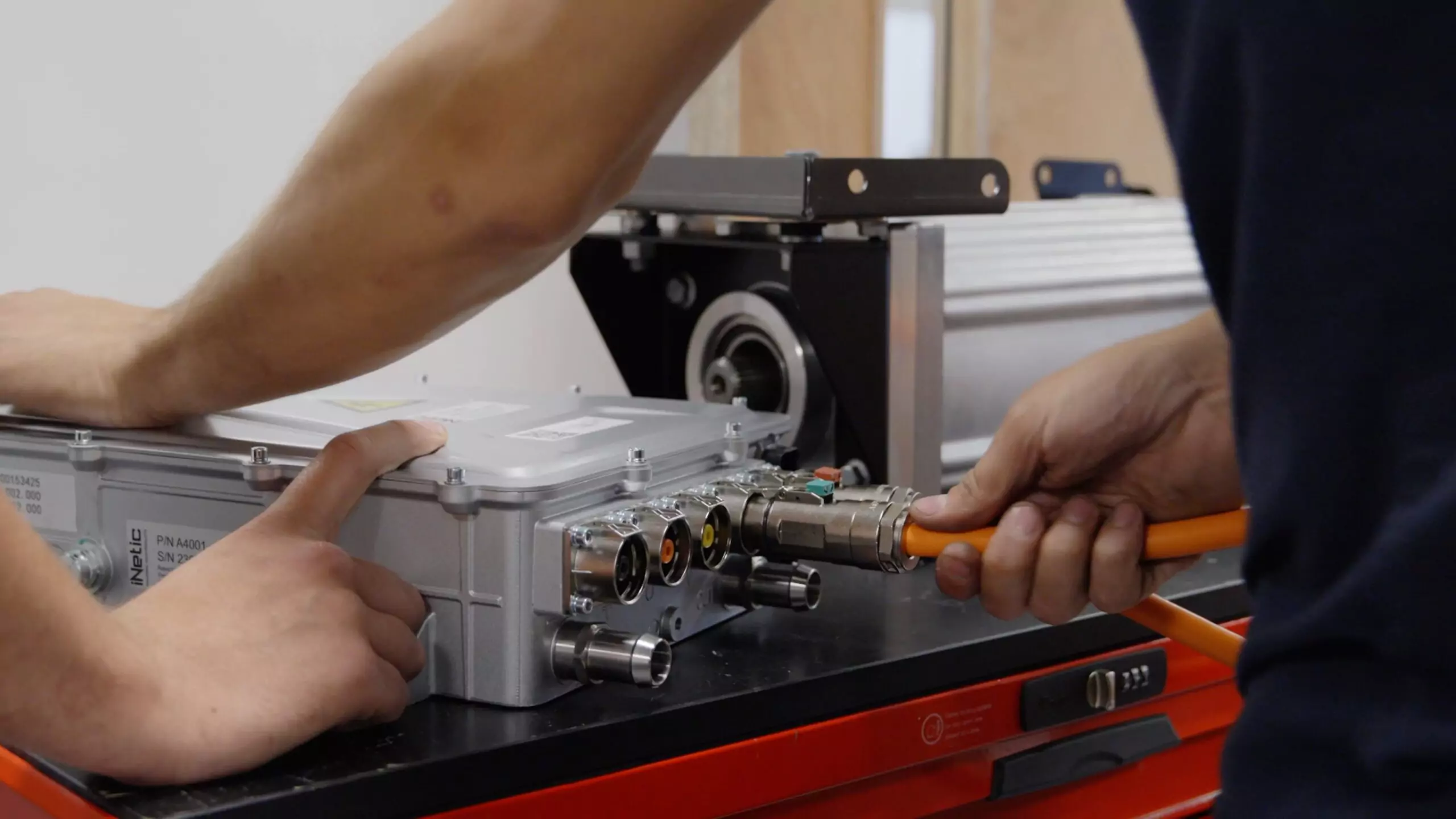

3. True IP6K9K Protection

Automotive “waterproof” (IP67) ratings fail instantly under pressure washing or slurry exposure. The iPA housing system is engineered for IP6K9K ingress protection, meaning it can withstand:

– Direct 100 bar (1450 psi) washdowns at 80 °C.

– Abrasive dust and mud ingress typical of construction and agricultural sites.

This makes the motor ideal for daily washdown operations without risk of corrosion or internal contamination.

4. Thermal Management Designed for Stall Conditions

Instead of relying on vehicle motion for cooling, iNetic’s iPA integrates robust liquid cooling systems—including optional direct oil cooling for stator and rotor regions. This approach removes heat even when the motor is stationary or working at stall. It ensures stable operating temperatures and prevents demagnetisation of the rare-earth magnets that deliver iPA’s high torque density.

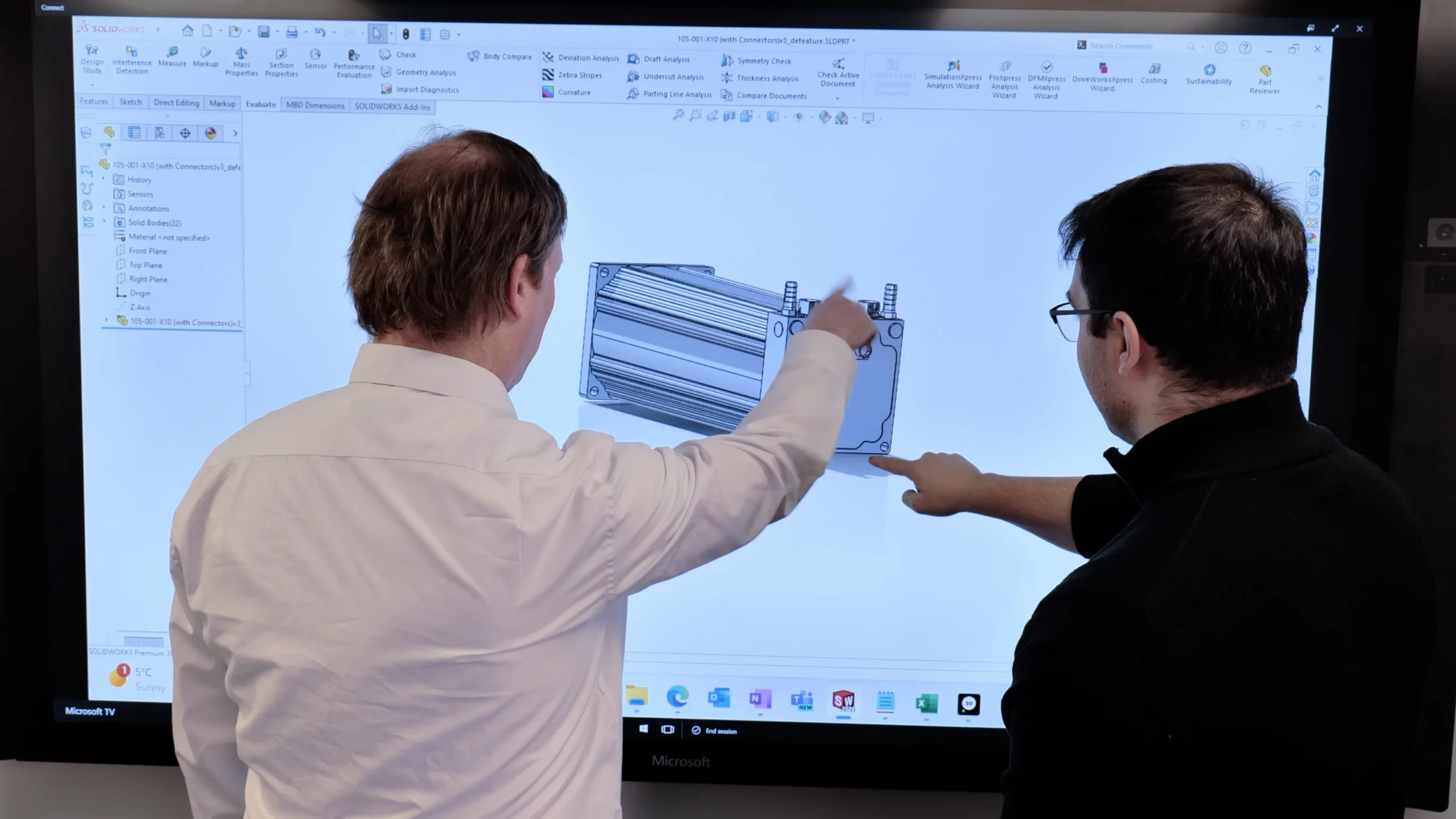

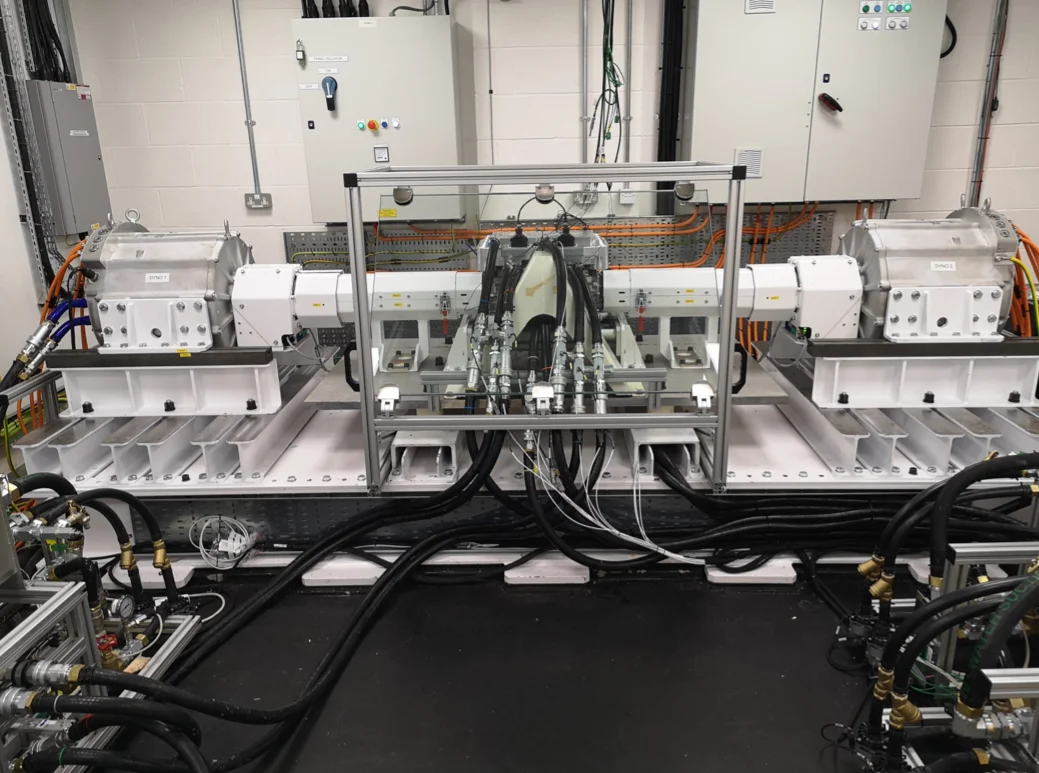

5. Integrated Architecture for Reliability

The iPA platform can be supplied as part of a fully integrated motor-inverter-gearbox (EDU) package. This eliminates external couplings and potential alignment issues. It simplifies installation and drastically reduces field failure points. The result is a compact, sealed, high-power system purpose-built for harsh off-road environments.

Why Automotive Motors Fail - and Why iPA Succeeds

| Parameter | Automotive PMSM | iNetic iPA Off-Highway PMSM |

|---|---|---|

| Design Goal | Range, weight, cost | Continuous power, reliability |

| Torque Profile | High peak torque, short duration | High continuous torque at low speed |

| Speed Range | 0–18,000 RPM | 0–6,000 RPM |

| Cooling System | Water-glycol, airflow-assisted | Robust liquid or direct oil cooling |

| Shock/Vibration Standard | Passenger-car (low-g) | SAE J1455 / ISO 15003 compliant |

| Ingress Protection | IP67 | IP6K9K (steam-jet & chemical wash) |

| Typical Lifetime in Off-Highway Duty | Weeks to months | Thousands of operational hours |

The Cost of Choosing Wrong

An excavator, loader, or mining truck is not a car – and its downtime costs are measured in thousands of pounds per hour. Selecting an automotive-grade motor might save money up front, but it introduces:

- Catastrophic thermal failures from sustained stall torque.

- Bearing and shaft failures from high-g shocks.

- Ingress and corrosion damage from pressure washing.

By contrast, the iPA’s purpose-built design delivers sustained reliability, predictable performance, and a dramatically lower total cost of ownership (TCO).

Purpose-Built, Proven, and Available Now

Off-highway electrification demands components designed for the job – not adapted from another industry. iNetic’s iPA series represents that evolution:

- PMSM architecture optimised for low-speed, high-torque operation.

- Mechanical and thermal robustness proven in real-world industrial use.

- Ingress protection and durability that match the harshest operating environments.

For OEMs, the choice is clear:

You can adapt an automotive motor – and manage endless failures.

Or you can deploy a purpose-built, production-ready iPA motor engineered for the exact challenges of the off-highway world.