Introduction

Electric vehicles (EVs) rely on two main types of motors for propulsion: AC induction motors and permanent magnet (PM) synchronous motors. Each technology has distinct operating principles and performance characteristics that influence vehicle efficiency, torque output, cost, and design decisions. Below we explore how each motor works, compare their performance metrics (efficiency, torque density, cost, maintenance, scalability), and provide guidance on choosing the right motor for an EV application.

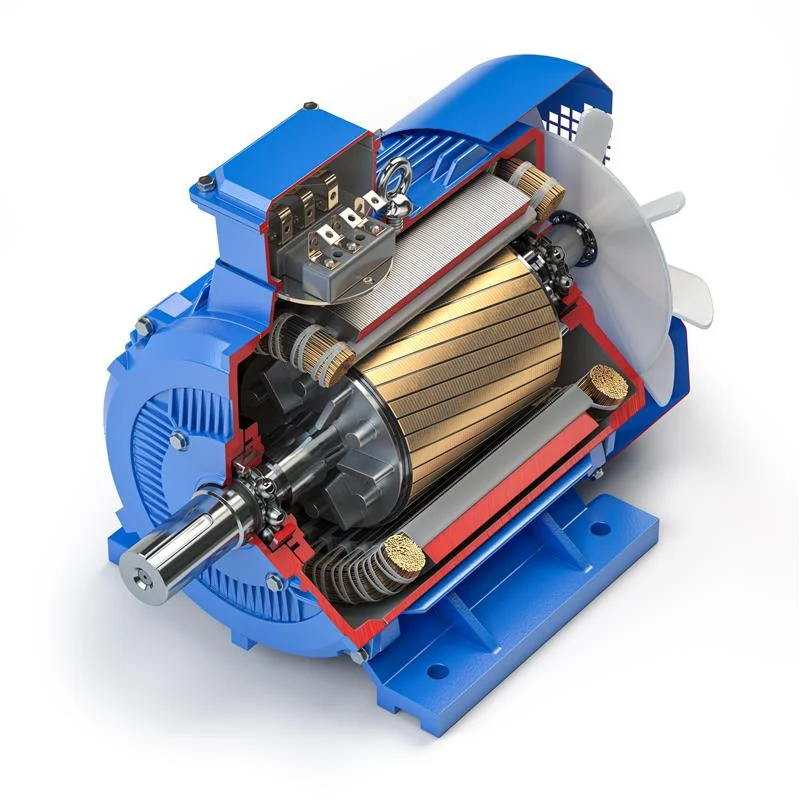

How AC Induction Motors Work

Principle: AC induction motors produce motion via electromagnetic induction. When alternating current flows through the stator windings, it creates a rotating magnetic field. This changing field induces currents in the rotor (typically a “squirrel cage” of copper or aluminium bars in a laminated steel core), causing the rotor to generate its own magnetic field and follow the stator’s rotation. The rotor always turns slightly slower than the stator’s magnetic field – a difference called slip, which is necessary to induce rotor current.

Key Traits: Induction rotors contain no permanent magnets; the magnetic field is temporary, arising only from induced current. This design is simple and robust, with no magnet material required. Induction motors have been used for over a century and are well known for their durability in industrial settings. However, because the rotor field is induced, the motor draws extra current to magnetise the rotor. This inherent slip and induced current lead to some unique performance characteristics and its characteristic torque-speed curve. Notably, induction motors canfreewheel with very low losseswhen no current is supplied; if the inverter isn’t energising the stator, the rotor spins freely with minimal drag since there’s no permanent magnetic field present.

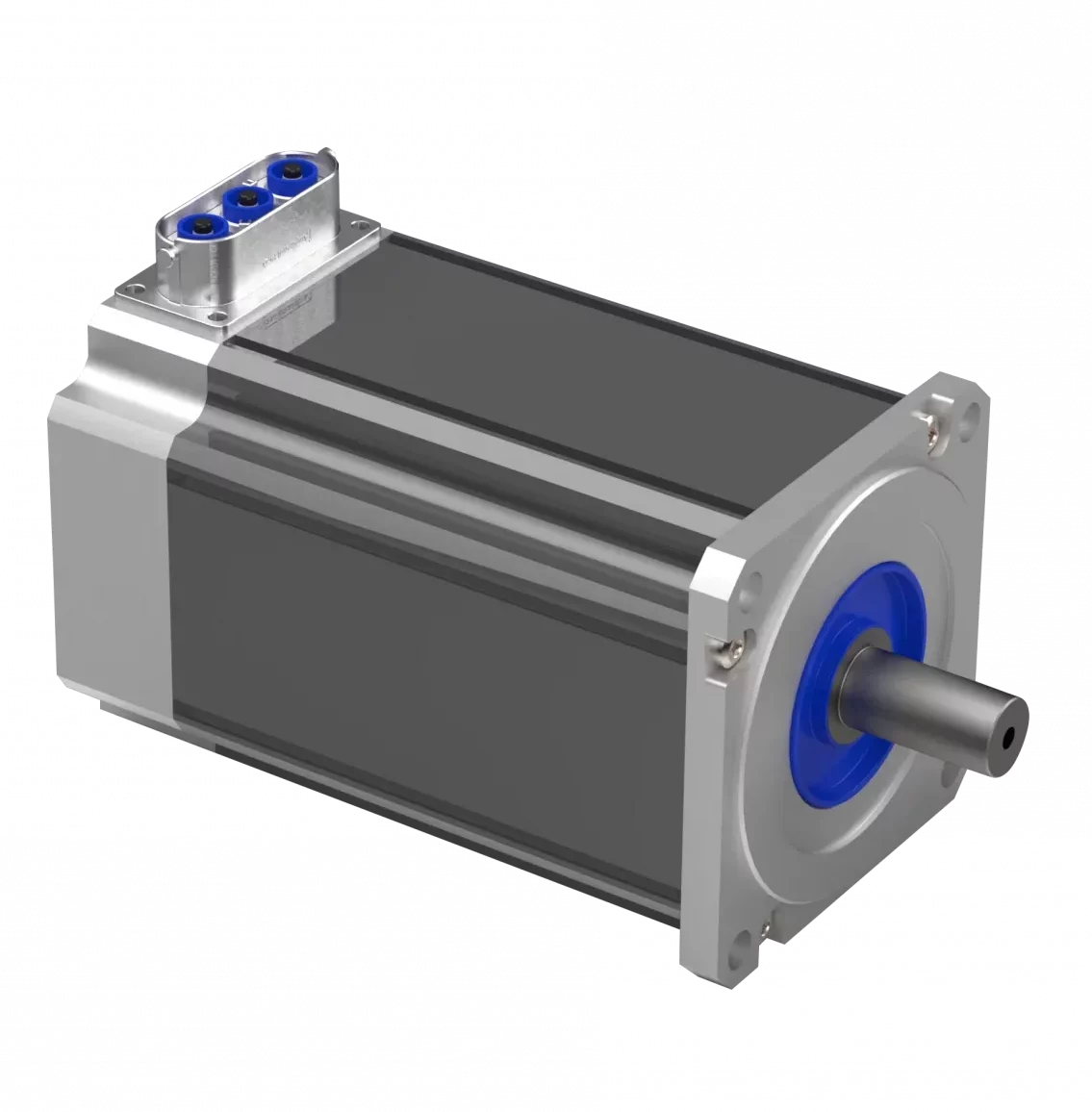

How Permanent Magnet Motors Work

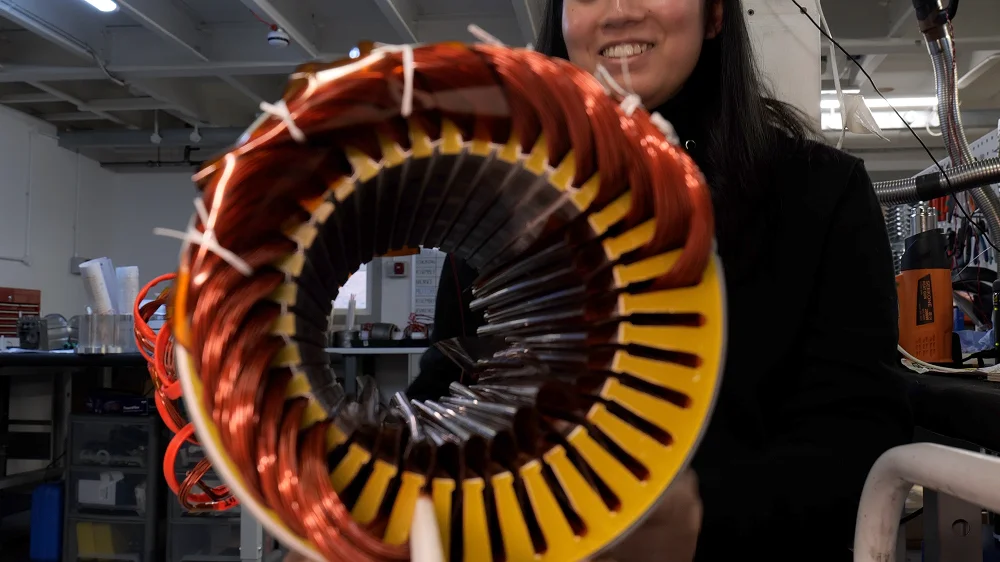

Principle: Permanent magnet synchronous motors (PMSMs) use built-in magnets (often rare-earth neodymium) in the rotor to create a constant magnetic field. When the stator windings are energised with AC (typically via an inverter), the stator’s rotating field locks onto the rotor’s field, and the rotor spins in sync with the stator field – hence “synchronous” operation. There is no slip under normal operation; the rotor turns at the same frequency as the stator’s rotating field, hence the name synchronous motor. Because the rotor’s magnetic field is always present, no induced current is needed in the rotor, eliminating the need for rotor windings or bars.

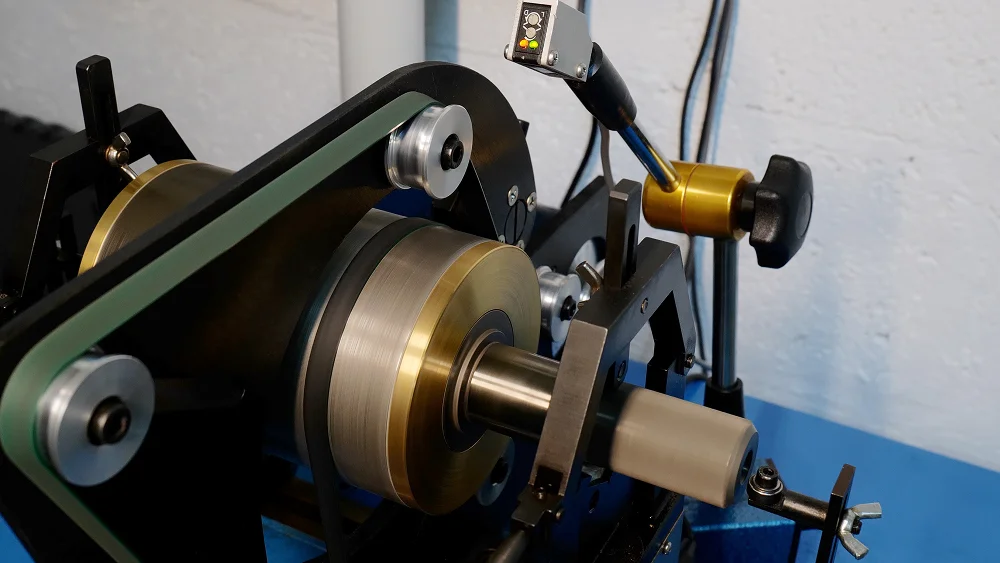

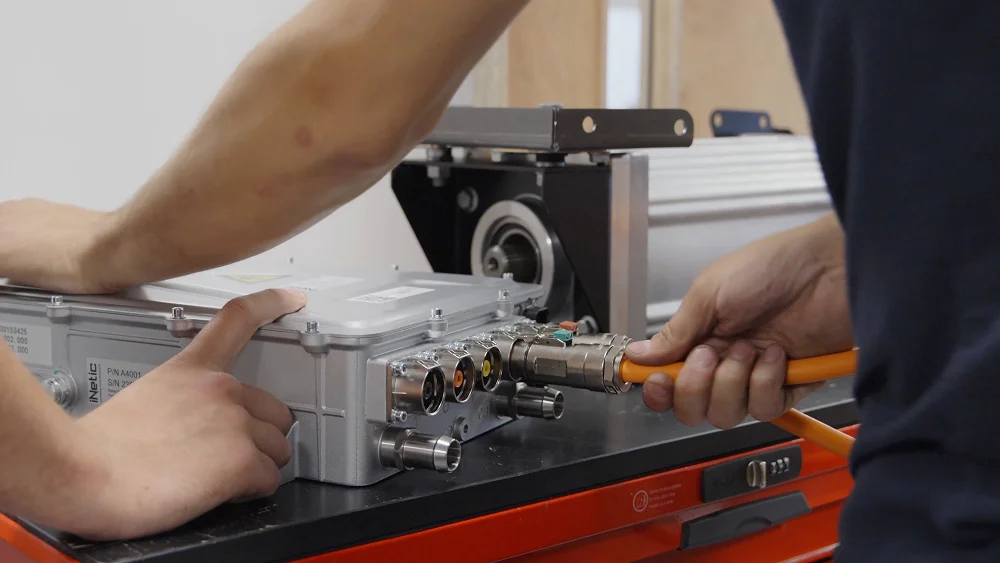

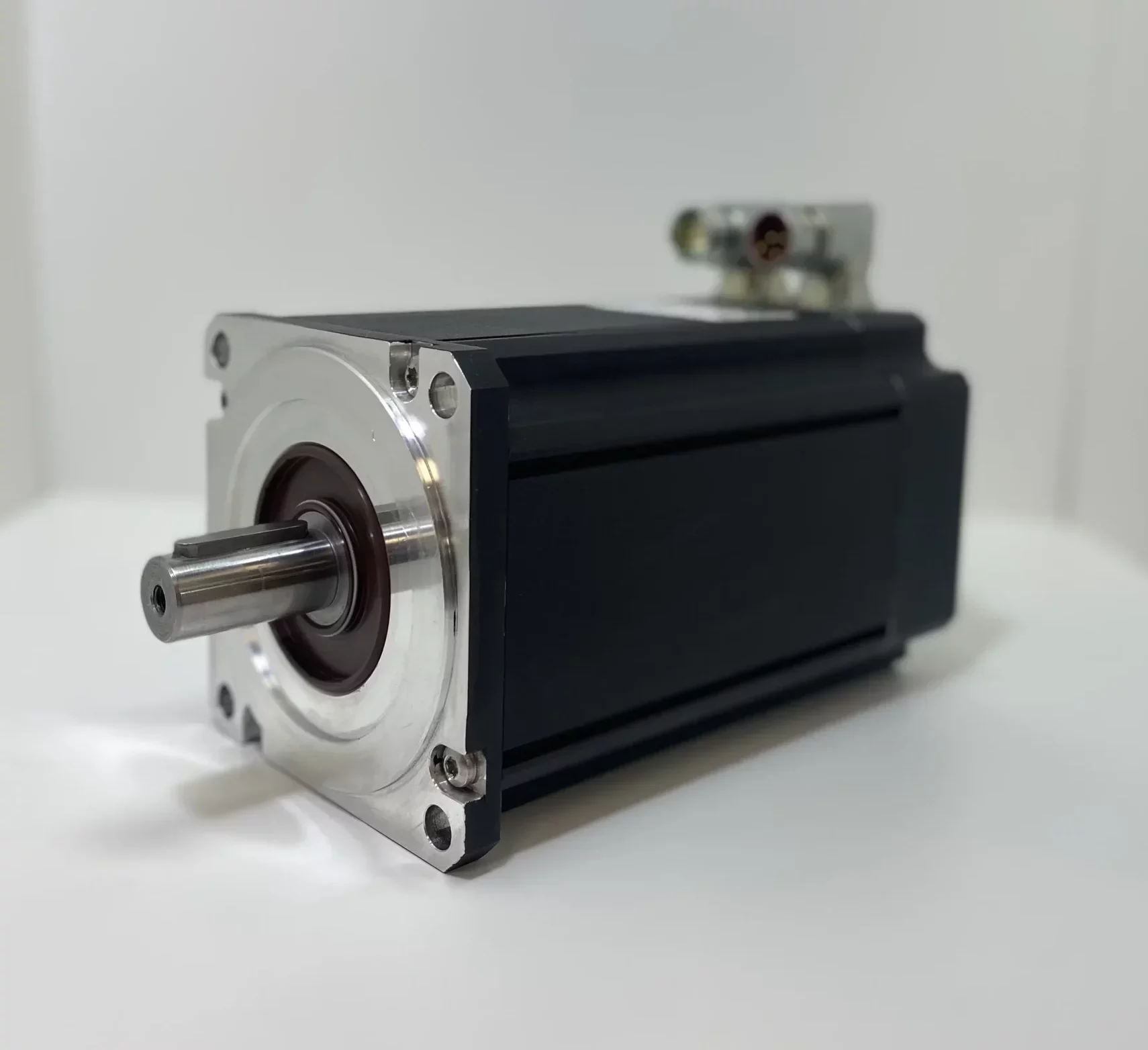

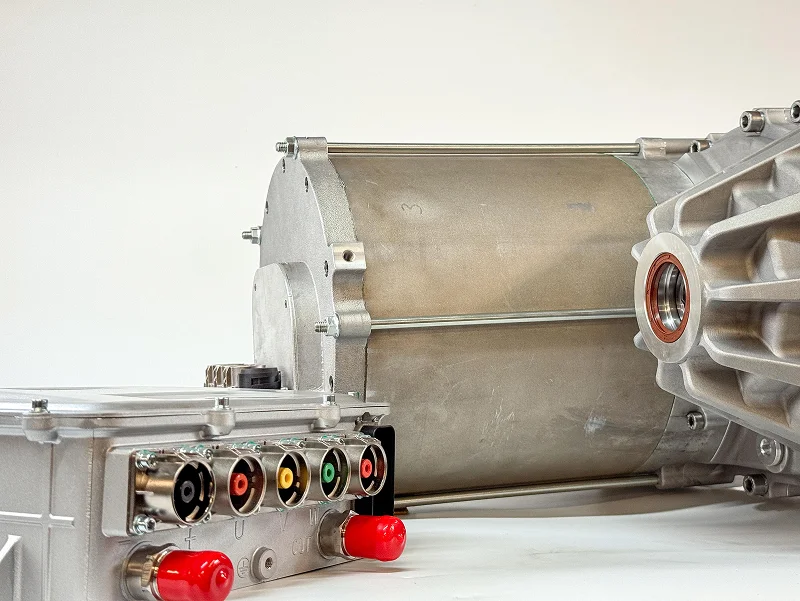

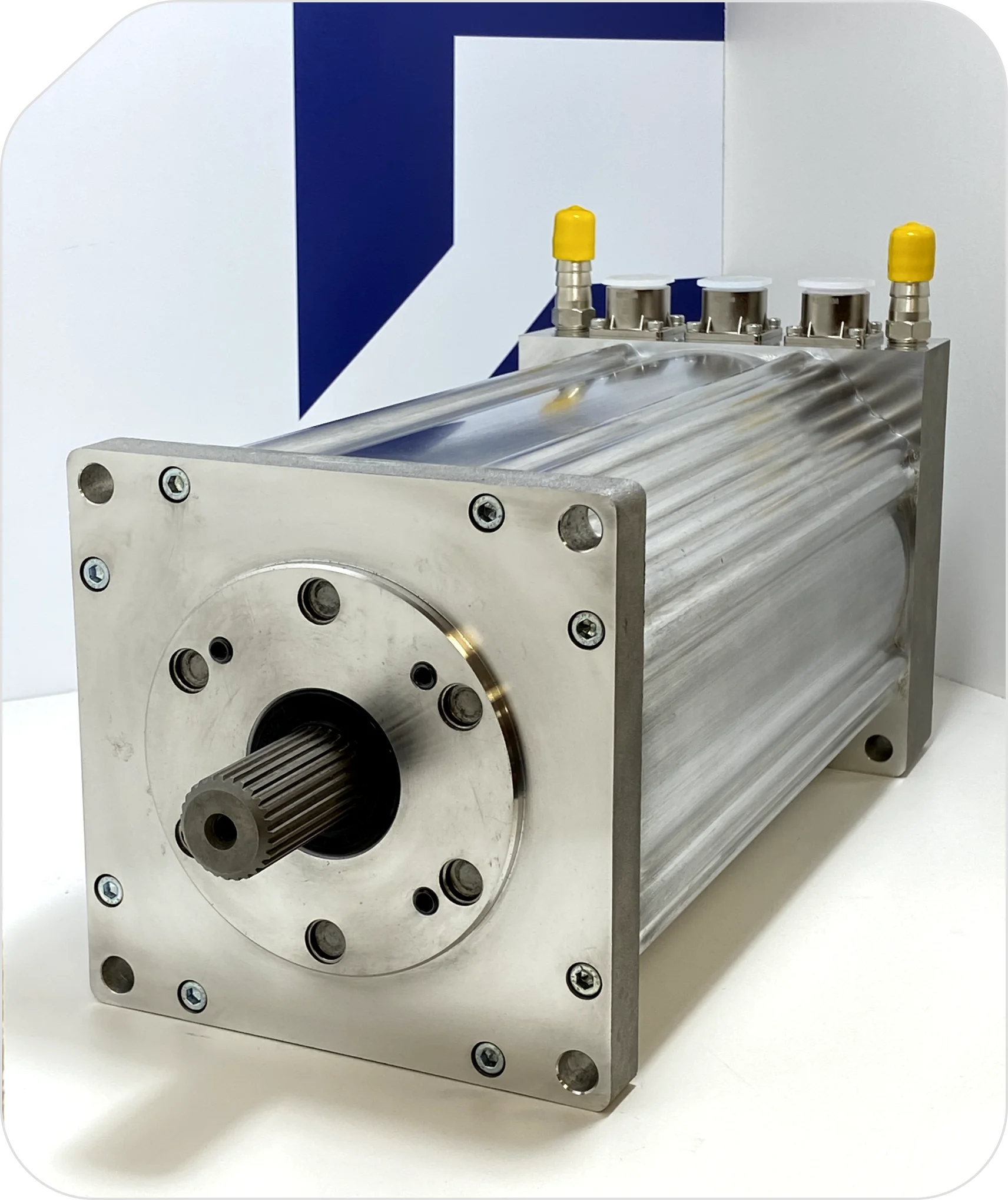

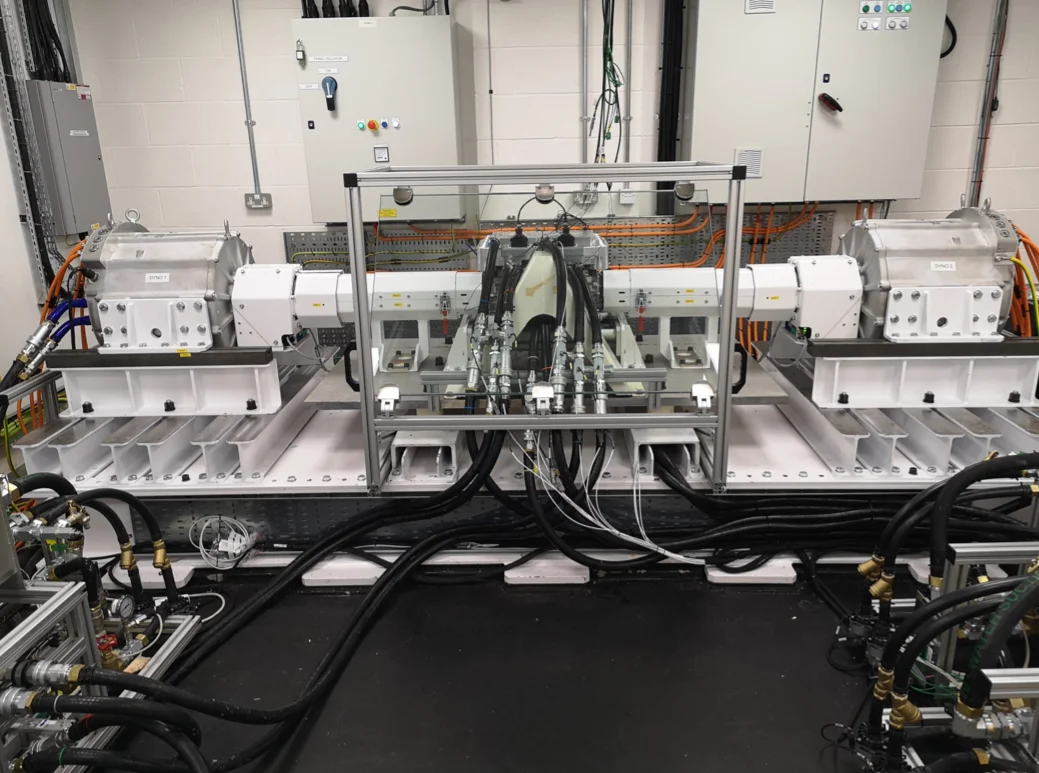

Key Traits: PM motors provide high magnetic flux from the rotor without drawing electrical current to create it. This gives high torque even at zero or low speed (since the magnets provide startup flux) and allows very precise control of torque and speed. PMSMs do require a controller that knows the rotor position (using sensors or algorithms) to commutate the phases correctly, as they can’t simply be plugged into a fixed AC frequency for variable-speed operation. The presence of strong permanent magnets means the motor always has some magnetic field, even when not energised, which leads to some differences in loss behaviour (discussed below). Modern PM traction motors, such as iNetic’s designs, often use interior-mounted magnets and advanced cooling to achieve high speeds and power levels in a compact form factor. For example, iNetic Traction’s iEV and rEV Motor Range features an interior permanent magnet rotor running up to 18,000 rpm with a modular, liquid-cooled design. This design provides exceptional performance for automotive use while maintaining reliability in volume production.

Induction Motor Efficiency

AC induction motors tend to have slightly lower peak efficiency than comparable PM motors. This is because some input energy is always used to induce the rotor field (causing resistive (I²R) losses in the rotor). Moreover, a small amount of slip is required, which produces heat. In practice, well-designed induction motors for EVs can reach around 90–93% peak efficiency under optimal load. However, efficiency drops at partial load or low speeds, as the motor still draws magnetising current and incurs rotor losses even when not producing high torque. The need to create both stator and rotor magnetic fields leads to more losses across a broad operating range. One upside is that when an induction motor is not under load (for example, cruising with one motor inactive), the absence of permanent magnets means it can be essentially de-energised and freewheel with minimal drag losses, improving coasting efficiency.

AC induction motors tend to have slightly lower peak efficiency than comparable PM motors. This is because some input energy is always used to induce the rotor field (causing resistive (I²R) losses in the rotor). Moreover, a small amount of slip is required, which produces heat. In practice, well-designed induction motors for EVs can reach around 90–93% peak efficiency under optimal load. However, efficiency drops at partial load or low speeds, as the motor still draws magnetising current and incurs rotor losses even when not producing high torque. The need to create both stator and rotor magnetic fields leads to more losses across a broad operating range. One upside is that when an induction motor is not under load (for example, cruising with one motor inactive), the absence of permanent magnets means it can be essentially de-energised and freewheel with minimal drag losses, improving coasting efficiency.

Permanent Magnet Motor Efficiency

Permanent magnet motors are known for their high efficiency, especially across varying loads. Because the rotor’s field is supplied by magnets, there are no rotor current losses and no slip. The motor can maintain synchronised rotation without wasted energy in the rotor. Efficiency ratings for PM traction motors can reach the mid-90s; modern designs achieve 95–97% peak efficiency. They also retain high efficiency at partial load, since no extra current is needed to sustain the magnetic field at low torque output. This superior efficiency (especially in stop-and-go or varying speed conditions) is a major reason why nearly all recent EV models have adopted PM motors, higher efficiency directly translates to better range. For instance, Tesla switched to a PM motor in the Model 3 primarily to improve range per battery charge. The trade-off is that a PM motor always has the magnet field present, so when the motor spins without a load it induces eddy currents and hysteresis losses in the stator (dragging on the rotation). In short, you can’t “turn off” a PM motor’s field, a PM rotor spinning freely will still generate some loss, meaning slightly less coasting efficiency. Overall though, under driving loads, PM motors’ efficiency advantage is significant, often giving a few percentage points better drivetrain efficiency than induction machines – a critical edge for EV range.

Permanent magnet motors are known for their high efficiency, especially across varying loads. Because the rotor’s field is supplied by magnets, there are no rotor current losses and no slip. The motor can maintain synchronised rotation without wasted energy in the rotor. Efficiency ratings for PM traction motors can reach the mid-90s; modern designs achieve 95–97% peak efficiency. They also retain high efficiency at partial load, since no extra current is needed to sustain the magnetic field at low torque output. This superior efficiency (especially in stop-and-go or varying speed conditions) is a major reason why nearly all recent EV models have adopted PM motors, higher efficiency directly translates to better range. For instance, Tesla switched to a PM motor in the Model 3 primarily to improve range per battery charge. The trade-off is that a PM motor always has the magnet field present, so when the motor spins without a load it induces eddy currents and hysteresis losses in the stator (dragging on the rotation). In short, you can’t “turn off” a PM motor’s field, a PM rotor spinning freely will still generate some loss, meaning slightly less coasting efficiency. Overall though, under driving loads, PM motors’ efficiency advantage is significant, often giving a few percentage points better drivetrain efficiency than induction machines – a critical edge for EV range.

Induction Motor Torque Density

Induction motors generally have lower torque density (torque per unit weight or volume) than PM motors. Because the flux in an induction motor is limited by how much current the stator can induce into the rotor (and by magnetic saturation limits of the iron), achieving high torque requires a larger size or more current (which adds heat). Thus, for the same output torque, an induction motor tends to be bulkier and heavier than a PM motor. For example, one industry comparison noted a ~50 kW PM motor could weigh under 30 lbs, whereas an equivalent ~55 kW (75 HP) industrial induction motor might weigh several hundred pounds. While that is an extreme case, it illustrates the point – more of an induction motor’s volume is occupied by iron and copper to generate the same flux that a PM motor can with compact magnets. Induction motors can still produce high peak torque (they have historically been used in performance EVs like the original Tesla Model S), but they usually need aggressive current input to do so, and their continuous torque capability is limited by heating.

Induction motors generally have lower torque density (torque per unit weight or volume) than PM motors. Because the flux in an induction motor is limited by how much current the stator can induce into the rotor (and by magnetic saturation limits of the iron), achieving high torque requires a larger size or more current (which adds heat). Thus, for the same output torque, an induction motor tends to be bulkier and heavier than a PM motor. For example, one industry comparison noted a ~50 kW PM motor could weigh under 30 lbs, whereas an equivalent ~55 kW (75 HP) industrial induction motor might weigh several hundred pounds. While that is an extreme case, it illustrates the point – more of an induction motor’s volume is occupied by iron and copper to generate the same flux that a PM motor can with compact magnets. Induction motors can still produce high peak torque (they have historically been used in performance EVs like the original Tesla Model S), but they usually need aggressive current input to do so, and their continuous torque capability is limited by heating.

Permanent Magnet Motor Torque Density

PM motors offer high torque and power density, meaning a smaller, lighter motor can produce the same (or greater) torque than a larger induction machine. The permanent magnets supply a strong flux in the rotor without bulk electromagnets, enabling a compact rotor design with high magnetic loading. Combined with high-energy magnet materials (e.g. NdFeB magnets with ~1.2–1.4 Tesla fields), this yields excellent torque in a small package. In fact, modern PMAC motors exceed the torque and power density of traditional AC induction designs. This is evident in high-performance EVs and motorsport: nearly all use PM motors for their superior power-to-weight ratio. For instance, iNetic Traction’s rEV Motor Range is specifically noted for its exceptional power-to-weight ratio, delivering up to 400 kW in a compact form factor suitable for demanding applications like racing and heavy commercial vehicles. Similarly, the smaller iFA and iPA series at iNetic focuses on optimal power density for applications like onboard hydraulics and fan applications. High torque density not only improves acceleration and performance but also helps with packaging in the vehicle, a lighter motor contributes to overall weight savings and potentially more interior or battery space.

PM motors offer high torque and power density, meaning a smaller, lighter motor can produce the same (or greater) torque than a larger induction machine. The permanent magnets supply a strong flux in the rotor without bulk electromagnets, enabling a compact rotor design with high magnetic loading. Combined with high-energy magnet materials (e.g. NdFeB magnets with ~1.2–1.4 Tesla fields), this yields excellent torque in a small package. In fact, modern PMAC motors exceed the torque and power density of traditional AC induction designs. This is evident in high-performance EVs and motorsport: nearly all use PM motors for their superior power-to-weight ratio. For instance, iNetic Traction’s rEV Motor Range is specifically noted for its exceptional power-to-weight ratio, delivering up to 400 kW in a compact form factor suitable for demanding applications like racing and heavy commercial vehicles. Similarly, the smaller iFA and iPA series at iNetic focuses on optimal power density for applications like onboard hydraulics and fan applications. High torque density not only improves acceleration and performance but also helps with packaging in the vehicle, a lighter motor contributes to overall weight savings and potentially more interior or battery space.

Induction Motor Cost

One of the strongest points in favour of induction motors is typically lower cost for a given power rating. Induction motors use conventional materials; steel laminations and copper/aluminium – and do not require expensive magnets. In high-volume production, the active material cost of an induction machine can be ~20–30% lower than that of an equivalent PM motor. This is primarily because permanent magnets (especially rare-earth magnets used for high performance) are costly components. Induction motors also avoid reliance on rare-earth supply chains, which can be a strategic advantage if magnet material prices are volatile. For OEMs building cost-sensitive EVs (such as entry-level models or commercial vehicles where upfront cost is critical), an induction motor might offer savings. The simpler rotor construction can also reduce manufacturing complexity. However, it’s worth noting that induction motors still require a sophisticated inverter and control software (similar to PM motors), so electronics costs are comparable. And any cost advantage must be weighed against efficiency: a less efficient induction motor may require a larger battery to achieve the same range, potentially offsetting motor cost savings with battery cost.

One of the strongest points in favour of induction motors is typically lower cost for a given power rating. Induction motors use conventional materials; steel laminations and copper/aluminium – and do not require expensive magnets. In high-volume production, the active material cost of an induction machine can be ~20–30% lower than that of an equivalent PM motor. This is primarily because permanent magnets (especially rare-earth magnets used for high performance) are costly components. Induction motors also avoid reliance on rare-earth supply chains, which can be a strategic advantage if magnet material prices are volatile. For OEMs building cost-sensitive EVs (such as entry-level models or commercial vehicles where upfront cost is critical), an induction motor might offer savings. The simpler rotor construction can also reduce manufacturing complexity. However, it’s worth noting that induction motors still require a sophisticated inverter and control software (similar to PM motors), so electronics costs are comparable. And any cost advantage must be weighed against efficiency: a less efficient induction motor may require a larger battery to achieve the same range, potentially offsetting motor cost savings with battery cost.

Permanent Magnet Motor Cost

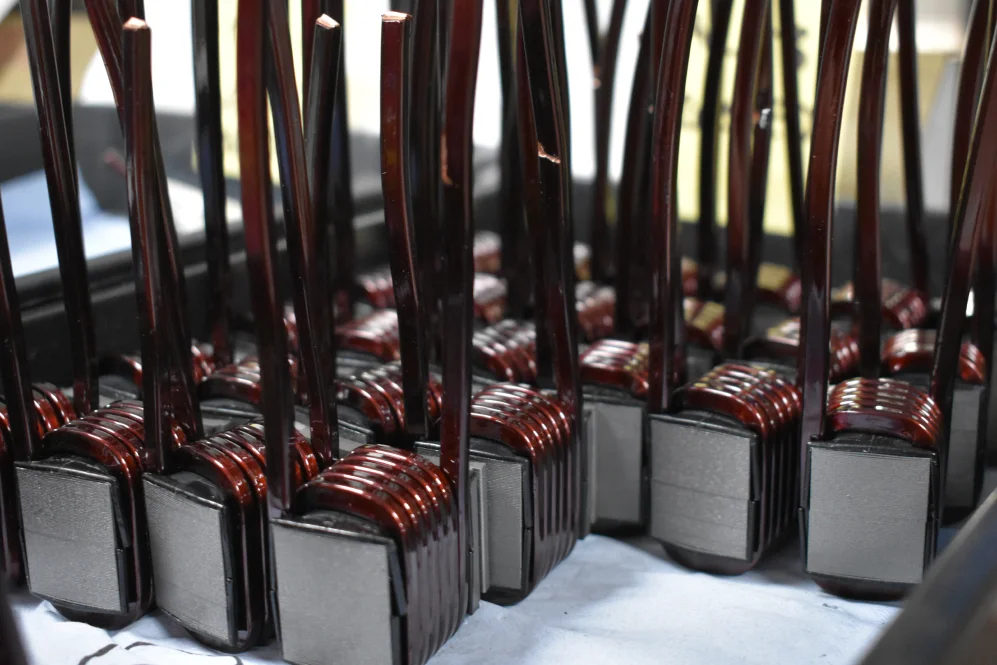

PM motors generally have a higher initial cost due to the magnets. High-performance neodymium magnets and their assembly into the rotor add expense. Manufacturers also often invest in precise rotor balancing and magnet retention techniques, which can increase production costs. Estimates show that a comparable PM traction motor’s active components might cost ~25% more than an induction motor’s. Additionally, the control of PM motors can be a bit more complex (requiring rotor position sensors or sensorless algorithms and safeguards against demagnetisation), but in modern designs, this is largely a solved problem and similar in complexity to vector-controlling an induction motor. Despite higher upfront cost, the efficiency of PM motors can yield cost benefits over the vehicle’s lifetime – energy savings (especially for a vehicle used daily) may outweigh the initial price difference. Also, as EV production scales up, economies of scale and improved magnet technologies (or use of less rare-earth content) are steadily reducing the cost gap. Many automakers have deemed the efficiency and weight advantages of PM motors worth the cost in today’s EV market, which is why PM machines dominate current EV designs despite higher material costs.

PM motors generally have a higher initial cost due to the magnets. High-performance neodymium magnets and their assembly into the rotor add expense. Manufacturers also often invest in precise rotor balancing and magnet retention techniques, which can increase production costs. Estimates show that a comparable PM traction motor’s active components might cost ~25% more than an induction motor’s. Additionally, the control of PM motors can be a bit more complex (requiring rotor position sensors or sensorless algorithms and safeguards against demagnetisation), but in modern designs, this is largely a solved problem and similar in complexity to vector-controlling an induction motor. Despite higher upfront cost, the efficiency of PM motors can yield cost benefits over the vehicle’s lifetime – energy savings (especially for a vehicle used daily) may outweigh the initial price difference. Also, as EV production scales up, economies of scale and improved magnet technologies (or use of less rare-earth content) are steadily reducing the cost gap. Many automakers have deemed the efficiency and weight advantages of PM motors worth the cost in today’s EV market, which is why PM machines dominate current EV designs despite higher material costs.

Induction Motor Maintenance

Both induction and PM motors are low-maintenance by design; they are both brushless (no commutators or brushes to wear out) and have only a few moving parts (the rotor on bearings). In practice, the primary maintenance considerations for both are cooling system health and bearing replacement after long life. Induction motors have a reputation for ruggedness. The absence of fragile components like magnets means an induction rotor can tolerate mechanical and thermal stresses to a degree. For example, temporary overheating of an induction motor will mainly risk the insulation of windings (which is similar to a PM motor’s stator), but there’s no risk of permanently weakening a magnetic field. Induction rotors are basically solid metal forms; they generally either work or, if severely overstressed, might crack/break (which is rare outside extreme conditions). In most EV use cases, an induction motor’s reliability is excellent, Tesla proved this with the Roadster and Model S, logging many miles on induction machines.

Both induction and PM motors are low-maintenance by design; they are both brushless (no commutators or brushes to wear out) and have only a few moving parts (the rotor on bearings). In practice, the primary maintenance considerations for both are cooling system health and bearing replacement after long life. Induction motors have a reputation for ruggedness. The absence of fragile components like magnets means an induction rotor can tolerate mechanical and thermal stresses to a degree. For example, temporary overheating of an induction motor will mainly risk the insulation of windings (which is similar to a PM motor’s stator), but there’s no risk of permanently weakening a magnetic field. Induction rotors are basically solid metal forms; they generally either work or, if severely overstressed, might crack/break (which is rare outside extreme conditions). In most EV use cases, an induction motor’s reliability is excellent, Tesla proved this with the Roadster and Model S, logging many miles on induction machines.

Permanent Magnet Motor Maintenance

PM motors are also very reliable, but there are a few additional considerations due to the magnets. Temperature is a critical factor; excessive heat can cause magnets to lose strength (a phenomenon accelerated if the motor exceeds certain temperature thresholds for the magnet grade). Most PM traction motors use high-temperature-rated magnets and have thermal management to avoid this. Nonetheless, sustained operation at very high temperatures can gradually demagnetise the rotor over time. Extreme overcurrent or a sudden short-circuit can also potentially demagnetise or physically damage magnets. If a PM motor’s magnets partially demagnetise, the motor will have permanently reduced performance and would require rotor replacement to fix, an unlikely failure in normal usage, but a point to note for abuse conditions. Another aspect is that the adhesive or mechanical retention for magnets must be robust, high-speed PM rotors need careful design to ensure magnets stay in place under centrifugal forces. Reputable manufacturers like iNetic Traction address these design challenges in their PM motors, testing for worst-case scenarios. In terms of general maintenance, PM motors don’t need any routine service different from induction motors (just keep them cool and the bearings lubricated). Both motor types are typically designed to last the life of the vehicle with minimal intervention. Overall, the reliability of PM motors in EVs has proven to be excellent, on par with induction machines, as long as the motor is operated within its design envelope (especially temperature and speed limits).

PM motors are also very reliable, but there are a few additional considerations due to the magnets. Temperature is a critical factor; excessive heat can cause magnets to lose strength (a phenomenon accelerated if the motor exceeds certain temperature thresholds for the magnet grade). Most PM traction motors use high-temperature-rated magnets and have thermal management to avoid this. Nonetheless, sustained operation at very high temperatures can gradually demagnetise the rotor over time. Extreme overcurrent or a sudden short-circuit can also potentially demagnetise or physically damage magnets. If a PM motor’s magnets partially demagnetise, the motor will have permanently reduced performance and would require rotor replacement to fix, an unlikely failure in normal usage, but a point to note for abuse conditions. Another aspect is that the adhesive or mechanical retention for magnets must be robust, high-speed PM rotors need careful design to ensure magnets stay in place under centrifugal forces. Reputable manufacturers like iNetic Traction address these design challenges in their PM motors, testing for worst-case scenarios. In terms of general maintenance, PM motors don’t need any routine service different from induction motors (just keep them cool and the bearings lubricated). Both motor types are typically designed to last the life of the vehicle with minimal intervention. Overall, the reliability of PM motors in EVs has proven to be excellent, on par with induction machines, as long as the motor is operated within its design envelope (especially temperature and speed limits).

Induction Motor Applications

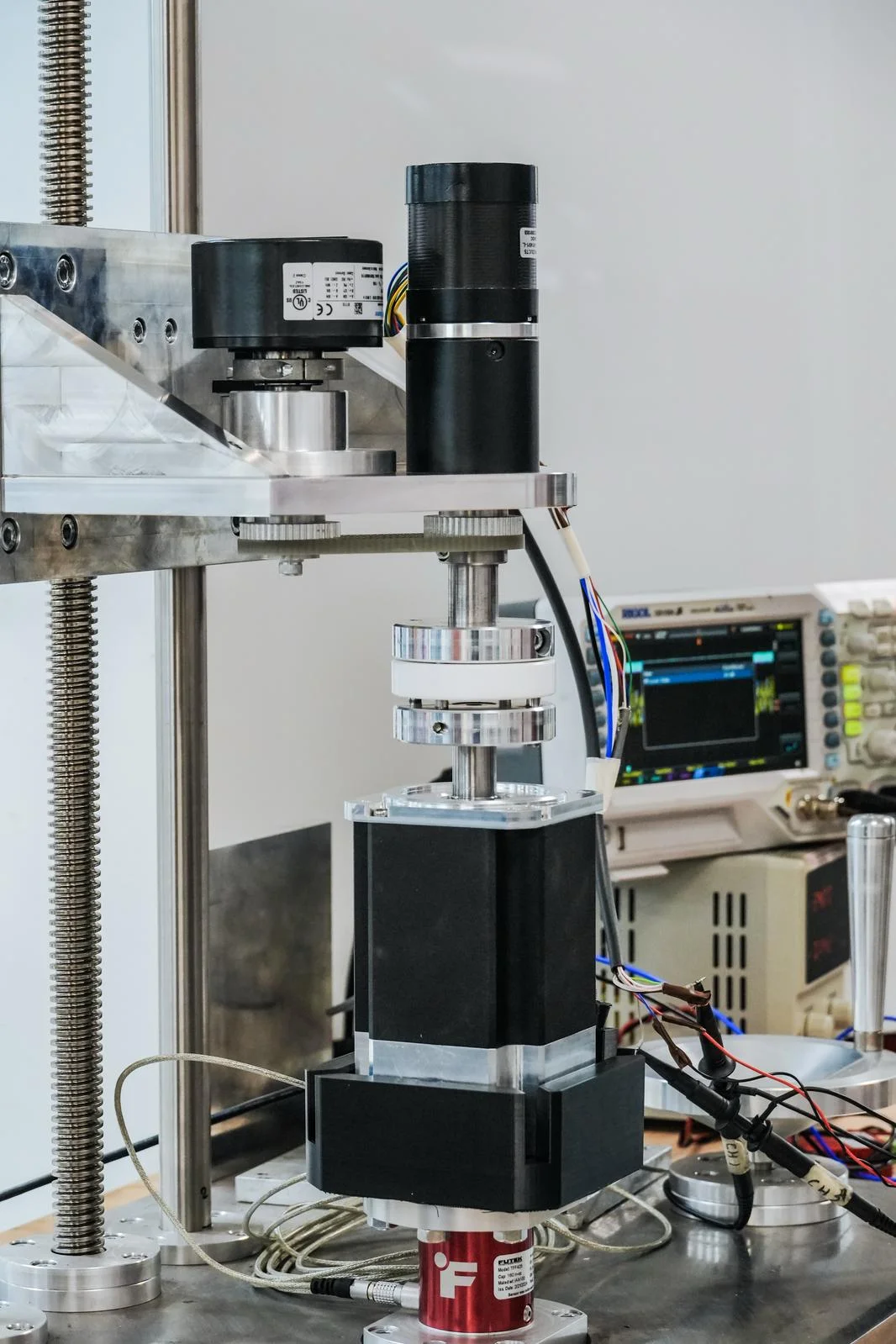

Induction motors have been produced in virtually every size and power, from tiny fractional-kW motors to multi-megawatt industrial drives. This scalability is an advantage in industrial contexts and was beneficial in early EV experiments. In the context of EVs, induction motors found use in some pioneering models (GM EV1, Tesla Roadster and Model S) and are still seen in certain applications. They can be a good choice for cost-sensitive EVs or those operating in extreme environments. For instance, an off-highway or high-performance vehicle that faces very high peak temperatures might opt for an induction motor to avoid magnet issues. Similarly, if an automaker wants to avoid reliance on rare-earth magnets due to supply chain concerns, induction is an alternative. Induction motors may also be considered in designs where a motor will often be spun without load or be shut off for efficiency (such as a multi-motor AWD setup where one axle’s motor can be deactivated at cruise). In fact, some dual-motor EVs use one induction motor alongside a PM motor to exploit this – the induction unit can be shut off and freewheel with virtually no drag when not needed, while the PM motor handles cruising efficiently. This strategy, used by Tesla in certain Model 3/Y configurations, highlights a niche strength of induction technology. Beyond cars, induction motors remain prevalent in heavy-duty applications (e.g. large electric trucks or buses in some cases) where initial cost savings and robustness might be prioritised over absolute efficiency (although as discussed, this can increase battery costs, leading to higher overview system costs).

Induction motors have been produced in virtually every size and power, from tiny fractional-kW motors to multi-megawatt industrial drives. This scalability is an advantage in industrial contexts and was beneficial in early EV experiments. In the context of EVs, induction motors found use in some pioneering models (GM EV1, Tesla Roadster and Model S) and are still seen in certain applications. They can be a good choice for cost-sensitive EVs or those operating in extreme environments. For instance, an off-highway or high-performance vehicle that faces very high peak temperatures might opt for an induction motor to avoid magnet issues. Similarly, if an automaker wants to avoid reliance on rare-earth magnets due to supply chain concerns, induction is an alternative. Induction motors may also be considered in designs where a motor will often be spun without load or be shut off for efficiency (such as a multi-motor AWD setup where one axle’s motor can be deactivated at cruise). In fact, some dual-motor EVs use one induction motor alongside a PM motor to exploit this – the induction unit can be shut off and freewheel with virtually no drag when not needed, while the PM motor handles cruising efficiently. This strategy, used by Tesla in certain Model 3/Y configurations, highlights a niche strength of induction technology. Beyond cars, induction motors remain prevalent in heavy-duty applications (e.g. large electric trucks or buses in some cases) where initial cost savings and robustness might be prioritised over absolute efficiency (although as discussed, this can increase battery costs, leading to higher overview system costs).

Permanent Magnet Motor Applications

PM motors have become the go-to solution for most modern EVs, from passenger cars to motorcycles to even heavy trucks, due to their superior efficiency and compact size. They scale well: designers can use multiple small PM motors for distributed drive (e.g. in-wheel motors or dual-motor setups) or build very large PM machines for buses and trucks (with appropriate magnet technology and cooling). Today’s magnet materials and motor designs allow PM traction motors to cover a wide range of power and torque. iNetic Traction’s product range is a good example of PM scalability – their sEV Motor Range addresses low-voltage and smaller EV needs (12 V up to 650 V systems, covering uses like e-bikes, fans and pumps), the iEV range spans mid-power applications (from ~5 kW up to 300 kW, suitable for mainstream automotive and marine uses), and the rEV series targets high-power applications (200–400 kW, for high-end passenger cars, motorsports, and heavy commercial vehicles). This demonstrates how PM motors can be engineered for everything from light urban mobility to high-performance racing. As EV adoption grows, the industry has largely standardized on PM motors for their blend of efficiency and performance. Even so, engineers must consider factors like magnet supply and operating environment. In some cases (e.g. a hypercar that might see repeated track abuse or a mining vehicle in extreme heat), they might add features like magnetic flux weakening or choose a different motor type if needed. Overall, PM technology continues to advance (for example, incorporating some reluctance torque to reduce magnet content), further extending its applicability. For most OEMs today, a PM motor is the first choice for an EV drivetrain, with induction reserved for special circumstances.

PM motors have become the go-to solution for most modern EVs, from passenger cars to motorcycles to even heavy trucks, due to their superior efficiency and compact size. They scale well: designers can use multiple small PM motors for distributed drive (e.g. in-wheel motors or dual-motor setups) or build very large PM machines for buses and trucks (with appropriate magnet technology and cooling). Today’s magnet materials and motor designs allow PM traction motors to cover a wide range of power and torque. iNetic Traction’s product range is a good example of PM scalability – their sEV Motor Range addresses low-voltage and smaller EV needs (12 V up to 650 V systems, covering uses like e-bikes, fans and pumps), the iEV range spans mid-power applications (from ~5 kW up to 300 kW, suitable for mainstream automotive and marine uses), and the rEV series targets high-power applications (200–400 kW, for high-end passenger cars, motorsports, and heavy commercial vehicles). This demonstrates how PM motors can be engineered for everything from light urban mobility to high-performance racing. As EV adoption grows, the industry has largely standardized on PM motors for their blend of efficiency and performance. Even so, engineers must consider factors like magnet supply and operating environment. In some cases (e.g. a hypercar that might see repeated track abuse or a mining vehicle in extreme heat), they might add features like magnetic flux weakening or choose a different motor type if needed. Overall, PM technology continues to advance (for example, incorporating some reluctance torque to reduce magnet content), further extending its applicability. For most OEMs today, a PM motor is the first choice for an EV drivetrain, with induction reserved for special circumstances.

Advantages of PM Motors (and Inetic Traction Solutions)

Permanent magnet motors offer several clear benefits for EV traction, which is why they dominate recent designs. Here’s a summary of PM motor advantages and how they reflect in iNetic’s PM motor products:

When to Consider Induction Motors

While permanent magnet motors are often the preferred choice, induction motors still hold relevance in certain scenarios. It’s important for OEMs and system designers to objectively consider requirements where an induction motor might be the better fit:

- Cost-Sensitive Designs: If minimizing the motor and drivetrain cost is a top priority (for example, in a budget EV model or a price-competitive commercial vehicle), an induction motor could be advantageous. You avoid the expense of rare-earth magnets and can potentially use a simpler supply chain. The cost savings on the motor must be weighed against any increase in battery capacity needed due to lower efficiency, but for short-range vehicles or those where energy is cheap, induction might win out on initial cost.

- High-Temperature or Harsh Environments: For applications that involve very high operating temperatures or frequent overload conditions, induction motors can offer peace of mind. Induction motors have no permanent magnetic material to be damaged by heat. This also extends to tolerance of abuse – an induction motor can often endure short-term overloads (causing temporary heating) without permanent damage, whereas a PM motor pushed too far could risk partial demagnetisation.

- Avoiding Rare-Earth Supply Dependencies: Some manufacturers may strategically choose induction motors to sidestep the supply and geopolitical issues surrounding rare-earth magnets (neodymium, dysprosium, etc.). If an OEM wants to ensure material availability or avoid price spikes in magnets, induction technology uses only common metals (steel, copper/aluminium). This can be a factor for very high-volume production or for regions where magnet sourcing is difficult.

- Certain High-Power Applications: In extremely high-power ranges (multi-megawatt drives, for instance) such as those in locomotives or large mining trucks, induction motors have a long track record. They can be simpler to scale up in size (no gigantic magnets to handle) and may be favoured for some heavy-duty drives. However, it’s worth noting that even here, PM machines are starting to penetrate (e.g. wind turbine generators, large ship propulsion motors are increasingly PM synchronous for efficiency). Nonetheless, if an application calls for a very large motor and efficiency is secondary to reliability and cost, induction might still be considered.

- Dual-Motor Systems (Freewheeling Axle): As mentioned earlier, one clever use of induction motors in EVs is in dual-motor AWD setups where one motor can be turned off during cruising. If an EV uses one induction motor and one PM motor, the induction unit can be completely de-energised when not needed, incurring virtually no magnetic drag. The vehicle can then cruise on the PM motor alone (for efficiency) and only engage the induction motor for extra power or traction. In such a design, the induction motor essentially adds power on demand without a continuous efficiency penalty when idle. OEMs evaluating AWD systems might consider this approach, as Tesla did in some Model 3 variants. It’s a niche scenario, but it showcases a specific role where induction technology shines in partnership with PM motors.

In all the above cases, the decision to use an induction motor should come from a careful analysis of trade-offs. It’s not that induction motors are “better” in general – it’s that they might align better with a particular project’s constraints (budget, environment, usage pattern). Good engineering practice is to choose the motor type that best fits the vehicle’s requirements rather than defaulting to one or the other.

Conclusion: Choosing the Right Motor for Your EV

For most electric vehicle designs today, permanent magnet motors have become the top choice due to their superior efficiency, high torque density, and excellent performance characteristics. They help maximise range and minimise weight, which are critical for EV success. The majority of new EV models, from compact cars to performance vehicles, feature PM motors in their drivetrains, and companies like iNetic Traction specialise in providing such advanced PM motor solutions to the industry.

However, choosing between an induction motor and a PM motor is not one-size-fits-all. OEMs and system designers should consider the following guidance when making this decision:

- Prioritise Your Goals: If your primary goals are to achieve the longest possible range, highest efficiency, and best power-to-weight ratio, a well-designed PM motor is likely the right choice. The efficiency gains will translate into real-world range and energy savings, and the compact size can simplify vehicle integration. On the other hand, if your project is extremely cost-constrained or will operate in conditions that challenge magnet technology (very high temperatures or risk of demagnetising events), an induction motor might be more suitable despite the efficiency trade-off.

- Consider the Use Case: Think about the typical duty cycle of the vehicle. Is it a commuter car that will see varied speeds and loads (favouring the broad efficiency of PM motors)? Is it a delivery truck where low-cost and robustness might outweigh a few percentage points of efficiency? Or perhaps a performance vehicle where every bit of torque and weight saving is crucial (again pointing to PM motors, possibly with specialised designs). iNetic’s range of PM motors shows that even high-power and high-speed applications can be handled by PM technology, so there are few performance-related reasons to avoid PM motors today. Induction might fill a niche for very specific use cases as discussed.

- Long-Term Outlook: Evaluate not just the upfront component costs, but the operational and lifetime costs. A more efficient motor (PM) can allow a smaller battery or lower electricity usage over the vehicle’s life – an important consideration for total cost of ownership and environmental impact. Also consider supply stability: magnet supply and prices have been reasonably stable recently, and many efforts are underway to recycle magnets and develop non-rare-earth magnets, potentially reducing future risks. In contrast, induction motors use commodities like copper, which can also fluctuate in price. Essentially, ensure that the choice will hold up economically over the production and service life of the vehicle.

- Innovation and Support: Keep in mind that motor technology isn’t static. Modern control electronics can mitigate some differences (for example, advanced controls can reduce induction motor losses at partial load, or protect PM motors from demagnetisation with clever current control). When in doubt, engage with motor experts or suppliers early. iNetic Traction, for example, not only provides off-the-shelf PM motors but also works with OEMs on custom motor design. Such partners can help analyse your requirements and even propose hybrid solutions (like integrating a reluctance component into a PM motor to reduce magnet content, or pairing motors in creative ways). Leverage their expertise to make an informed choice.

In conclusion, permanent magnet motors offer industry-leading efficiency and performance for EVs, which is why they are prevalent in the current generation of vehicles. Induction motors, while less common now in new designs, still have their place for certain niches and should remain in the engineer’s toolkit of options. A balanced, data-driven comparison of the two technologies, as we’ve provided here, will aid OEMs and system designers in selecting the optimal traction motor for their specific EV project. By understanding the trade-offs and benefits, and by working with experienced suppliers (such as exploring iNetic Traction’s PM motor offerings for high-performance, efficient solutions), decision-makers can confidently choose the motor technology that will deliver the best results for their electric vehicle vision.