Testing Capabilities

Our testing capabilities videos series starting with episode 1 : Motor Testing with Red – Exploring Resistance & Induction of Copper Coils!

If you are interested to watch the entire series, please use the below link.

Testing Capabilities

Our testing capabilities videos series starting with episode 1 : Motor Testing with Red – Exploring Resistance & Induction of Copper Coils!

If you are interested to watch the entire series, please use the below link.

End of line Testing

End of line Testing

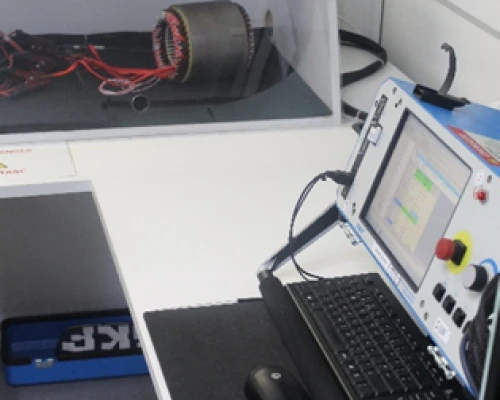

iNetic’s end-of-line testing capability is engineered to ensure the highest quality and reliability of our products, adhering to rigorous industry standards. Our automated test equipment (ATE) integrates advanced technologies, including high-precision sensors, programmable logic controllers (PLCs), and sophisticated software for comprehensive functional testing. This equipment is capable of executing detailed inspections and performance evaluations, detecting defects, and validating product specifications with remarkable accuracy. By implementing these robust testing protocols, we not only guarantee compliance with relevant safety and quality standards but also enhance production efficiency and product consistency, ensuring that every unit meets our stringent quality criteria before reaching the market.

Performance Testing

Performance Testing

iNetic’s performance testing capabilities are exemplified by our state-of-the-art 400kW back-to-back dynamometer, which is pivotal for motor efficiency mapping, motor characterization, and inverter calibration. This advanced equipment allows us to perform rigorous and precise performance evaluations, adhering to industry standards. Our dynamometer facilitates comprehensive testing scenarios, enabling us to measure torque, speed, and power under various load conditions, ensuring optimal performance and efficiency. This thorough analysis helps in fine-tuning motor and inverter parameters, leading to enhanced reliability and performance of the final product. By leveraging such high-capacity testing infrastructure, iNetic ensures that every motor and inverter we produce meets the highest standards of efficiency and durability, reinforcing our commitment to excellence in performance testing.

Durability Testing

Durability Testing

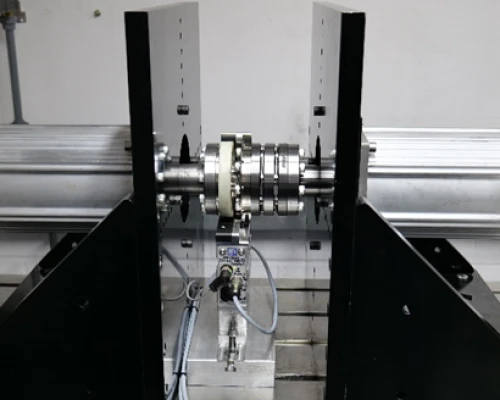

iNetic’s durability testing capabilities are underscored by our ability to design custom rigs tailored to meet a diverse array of requirements. Our bespoke testing solutions are engineered to simulate real-world operating conditions, ensuring that our products can withstand prolonged usage and harsh environments. These custom rigs allow us to conduct accelerated life testing, fatigue analysis, and stress testing, providing detailed insights into the longevity and robustness of our components. By meticulously assessing wear and tear, material degradation, and performance under extreme conditions, we guarantee that our products are not only reliable but also capable of maintaining their functionality over extended periods. This rigorous approach to durability testing ensures that every product we deliver meets the highest benchmarks for endurance and reliability, reinforcing our commitment to quality and innovation.