Mission statement

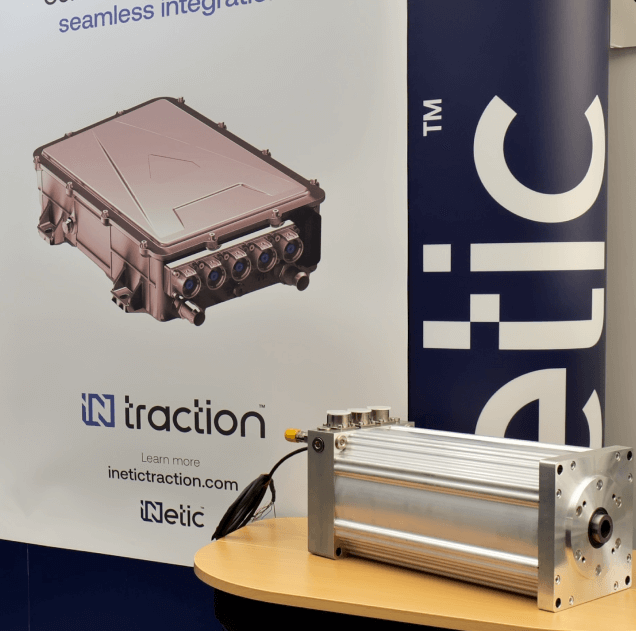

Collaborating with Drivetrain Experts for Procurement Success

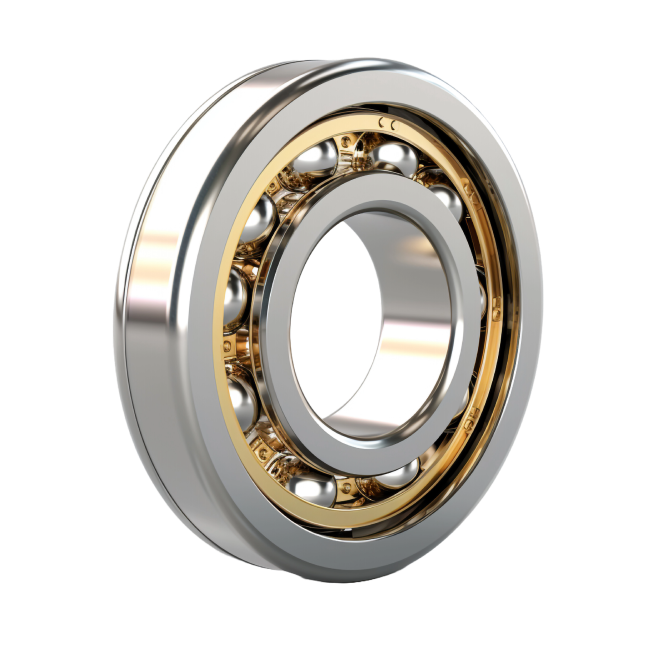

Our unparalleled reliability ensures seamless integration into diverse projects, guaranteeing optimal performance and longevity for your esteemed operations.

Our unmatched flexibility ensures smooth integration into any project, adapting seamlessly to diverse requirements. With agile solutions tailored to your needs, we guarantee optimal performance and enduring success for your operations.

Client satisfaction is paramount. Our customer-centric philosophy means that companies experience personalized attention, streamlined communication, and bespoke solutions.

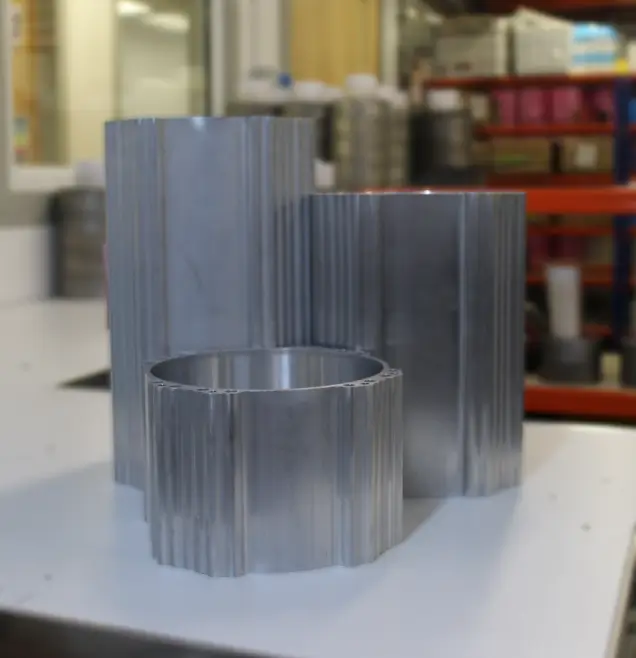

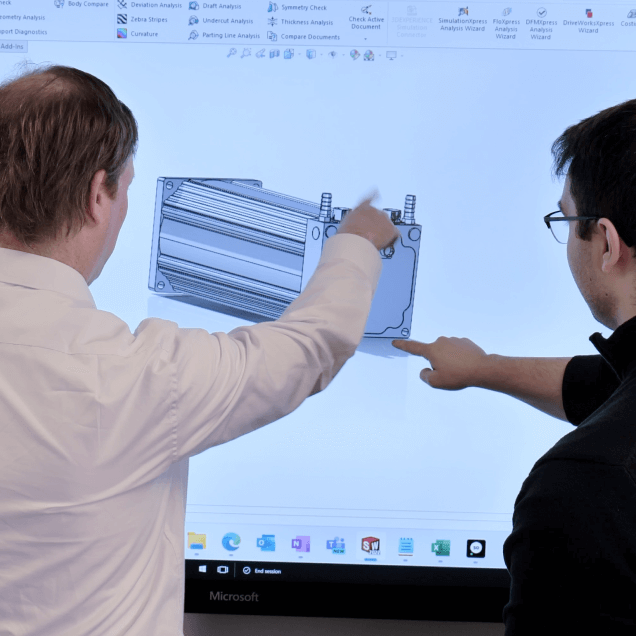

iNetics’ approach to design is inherently focused on manufacturing efficiency, ensuring that every product we create is designed to be produced with precision, cost-effectiveness, and scalability in mind.

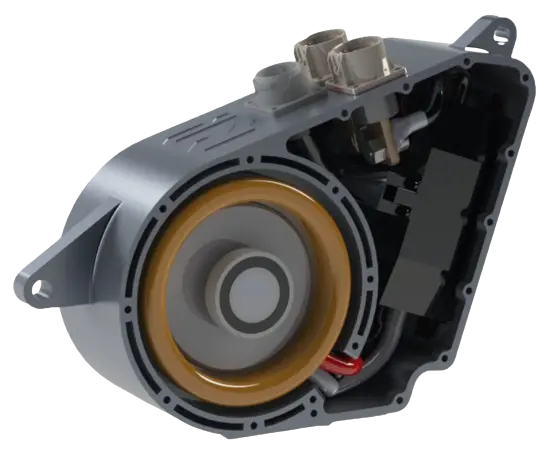

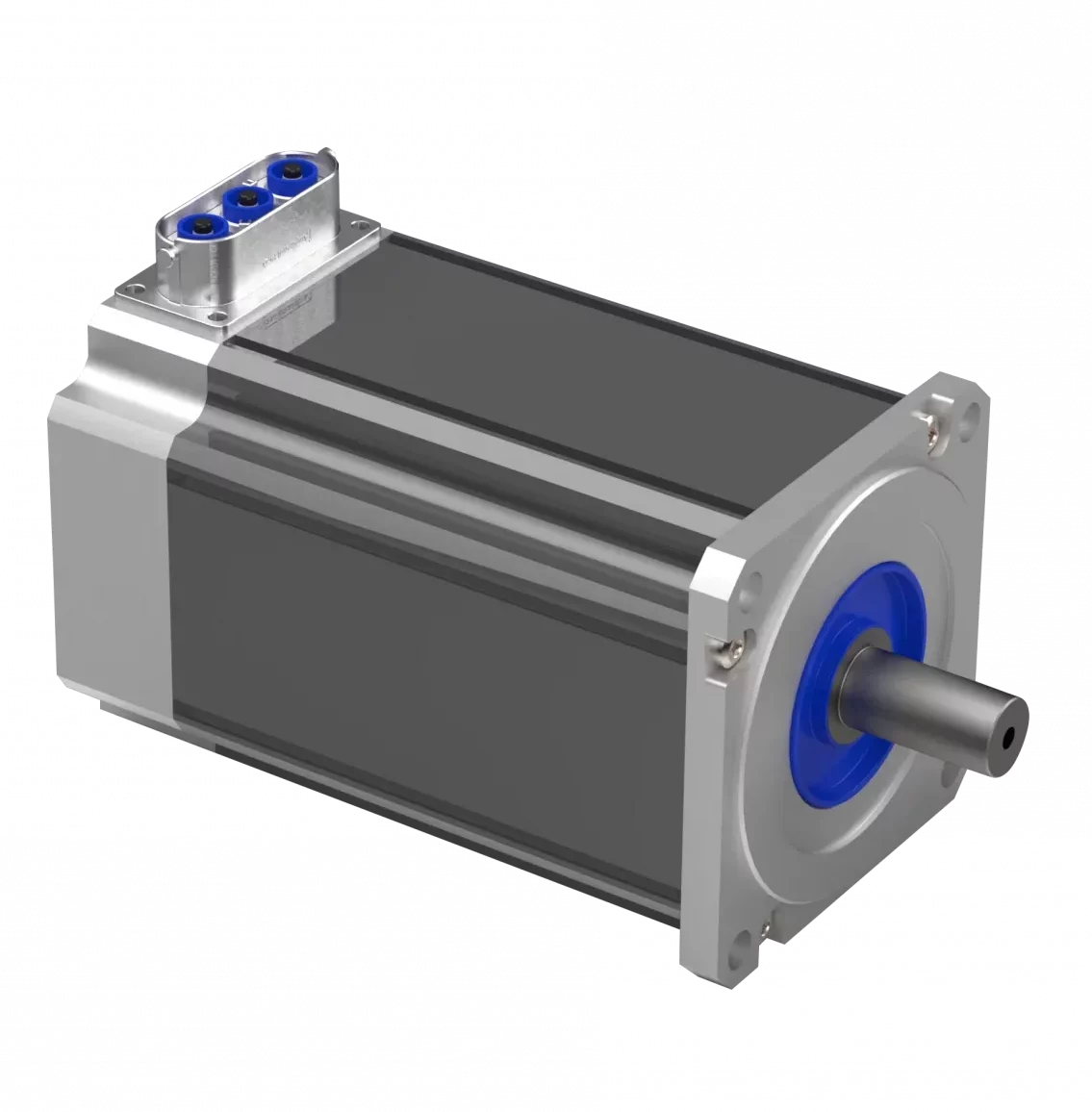

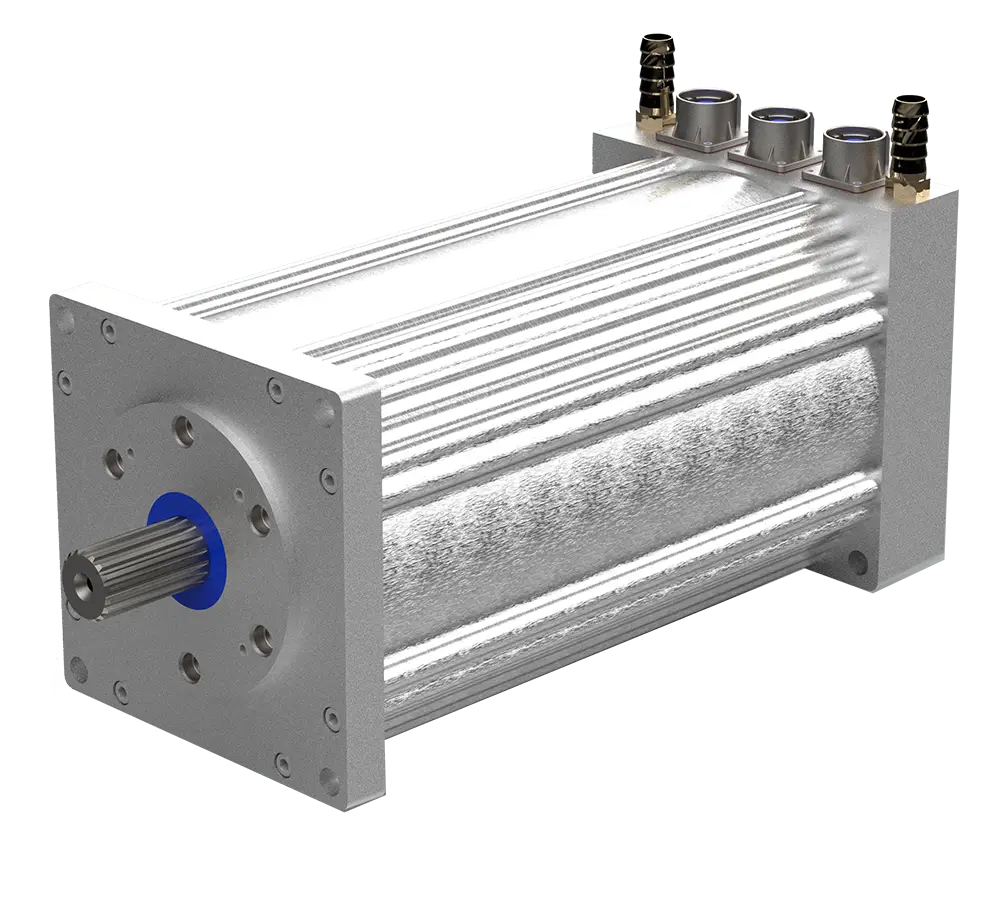

We Make Groundbreaking Motor Designs That Set Industry Standards

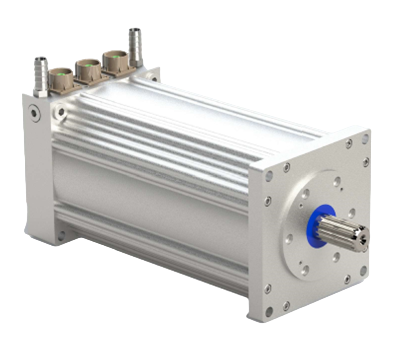

Featured motors available on our shelves

Engineering Insights

Why Marine Electrification Starts with Compliance

Marine electrification promises cleaner, quieter vessels – but bringing electric propulsion to the seas isn’t as simple as dropping a Tesla drivetrain into a ship. The maritime domain is governed by strict regulations and classification society rules that make compliance a foundational design consideration, not an afterthought. In fact, ensuring regulatory compliance from day one is often the only way to turn bold electrification concepts into practical realities on the water. This article explores why compliance comes first in marine electrification, how marine rules shape technical design (from electrical safety and redundancy to EMC and fire protection), and what it means for system-level engineering. We’ll also look at real-world projects (ferries, workboats, offshore vessels) where a compliance-first approach paved the way for success, and conclude with why marine-savvy integration partners are key in this emerging field.

Emerging Battery Technologies

In the quest to surpass conventional lithium-ion batteries, several next-generation chemistries are gaining momentum. Below is a comparative look at four prominent contenders – Lithium-Air, Sodium-Ion, Solid-State, and Semi-Solid-State batteries – focusing on their key characteristics, recent breakthroughs, leading players, commercialization timelines, and technical challenges. A summary table and detailed analysis for each chemistry are provided for a global, engineering-oriented audience.

The Hidden Impact of Auxiliary Systems on EV Efficiency and Range

Electric vehicle (EV) engineers often invest millions to improve the main powertrain’s efficiency by fractions of a percent. Traction motors and inverters in modern EVs can already exceed 95% efficiency[1], so squeezing out an extra 0.1% is a costly challenge. Yet too often this hard-won gain is negated by overlooked auxiliary systems – the small motors and devices that support cooling, heating, steering, and other functions.

Emerging Battery Technologies

In the quest to surpass conventional lithium-ion batteries, several next-generation chemistries are gaining momentum. Below is a comparative look at four prominent contenders – Lithium-Air, Sodium-Ion, Solid-State, and Semi-Solid-State batteries – focusing on their key characteristics, recent breakthroughs, leading players, commercialization timelines, and technical challenges. A summary table and detailed analysis for each chemistry are provided for a global, engineering-oriented audience.

The Hidden Impact of Auxiliary Systems on EV Efficiency and Range

Electric vehicle (EV) engineers often invest millions to improve the main powertrain’s efficiency by fractions of a percent. Traction motors and inverters in modern EVs can already exceed 95% efficiency[1], so squeezing out an extra 0.1% is a costly challenge. Yet too often this hard-won gain is negated by overlooked auxiliary systems – the small motors and devices that support cooling, heating, steering, and other functions.